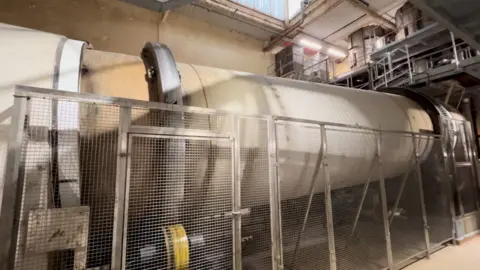

The factory processing 20,000 tonnes of sugar beet a day

BBC

BBCThe process of farming and refining sugar beet in Britain hasn't changed much, but the power and the machinery behind it have.

In 1925, a fledgling sugar factory in Norfolk managed to process 600 tonnes of sugar beet in a day.

Now it can get through that in an hour.

The British Sugar factory at Wissington, an eight-mile (13km) drive from Downham Market, is now dubbed "the largest and the most cost effective sugar processing site in Europe", processing 20,000 tonnes of beet a day.

General manager Elliot Fisher has been working at the Wissington factory since he was 16 years old.

"One way to run a sugar factory for real energy efficiency is you run it full and you run it fast," he said.

On an average week day, he says, 1,000 lorries will arrive full of sugar beet to stack onto flat pads, each of which can hold 55,000 tonnes of beet.

The factory is supplied by more than 1,000 growers from Norfolk, Cambridgeshire and Lincolnshire, with the average distance between farm and factory about 28 miles.

Next, the beet is washed, with weeds, stones and other foreign materials filtered out.

The beet then goes into "hoppers", to be sliced.

"The slicer building is where we slice just below 800 tonnes of sugar beet an hour," Mr Fisher added.

"To get the sugar out, you have to diffuse the sugar in hot water. The first thing to do is break the sugar down into slices. Think of some French fries look."

The slice quality "is everything" to the operation, he said, with the beets getting an air blast to ensure the "optimum cutting edge".

The beets then go into diffusers, which extract the sugar before being sent for purification.

All of the non-sugars are removed, until a thick sugary juice is left.

Once purified, the juice goes through evaporation to remove all the water, and sent to the refinery to crystalise into white sugar.

It's then transferred into either a 25kg bag, a bulk tanker or into liquid sugar.

The factory operates 24 hours a day, seven days a week from September to February.

Mr Fisher says they run a "lean operation" through automation, with advances in machinery seeing dramatic changes on the factory floor over its 100-year history.

"The last 100 years, the actual process of sugar hasn't changed hugely," Mr Fisher added.

"But this site has dramatically changed.

"The original design was for Wissington to slice around 600 tonnes a day of sugar beet; we now slice more than that in one hour.

"The knock on of how many this industry does employ is huge. For Norfolk itself and Suffolk and up at Newark, it's a great British product we can be really proud of.

"Grown in this country, processed in this country. A real British product."

Pete William Legge, of Legge Farms, works three miles from the Wissington factory, supplying sugar beet to it along with other locations.

His grandfather began the farm in 1961, passing down to his father in the 1970s - and then to him.

Mr Legge has seen radical changes to the farm operations, from manually chopping a small acreage, to achieving "huge amounts" with precision machinery.

But one thing that hasn't changed is how important sugar is for the county.

"It's a very lean time for agriculture across pretty much every commodity," he said.

""But [sugar] is a mainstay, for all of Norfolk it's a hugely important crop. Even if it's not massively profitable you can take some pride in those bigger crops.

"Perhaps the 10-, 15-tonne-an-acre crops that my grandfather was growing, were very pleasing. Now, we feel like we have to do 40 tonnes an acre and I think this year largely speaking we have."

Follow Norfolk news on BBC Sounds, Facebook, Instagram and X.