Shaping

There is a variety of equipment and processes used with timber, for example:

- hand tools for marking out, cutting and shaping, eg engineer’s squareA tool used to make 90 degrees. for marking lines at 90° to an edge

- machinery, eg circular saws and bandsaws

- digital design and manufacture, eg laser cutters and computer numerical controlled (CNC) routerA method by a computer to execute a pre-programmed sequence. Machines move via numerical values along X, Y and Z axes.

Cutting

There are a great many saws used to cut timber - some suit long straight cuts on thicker planks, and others suit curves and complex shapes:

- rip saw - for ‘ripping’ through and rough cutting thicker planks and boards

- tenon saw - for cutting straight lines with accuracy

- coping saws, jig saws and scroll saws - all for cutting thinner pieces of timber, and can cope with curves too

Shaping

Timber can also be drilled by using a variety of different drill bits, which work by twisting into a piece of timber:

- twist drills - used to simply drill a hole of a fixed diameterA straight line which joins two points on the circle and passes through the centre is a diameter. into a piece of timber

- countersink bits - used to profile a hole so that the top of a screw can sit flush with a surface

- forstner bits - used to drill flat-bottomed holes

- hole saws - used to cut large holes

Image caption, Image caption,

1 of 2

As well as cutting and drilling, there are other skills to develop to shape timber:

- chiselTo remove timber with a sharp cutting tool. - used to remove timber, usually up to a cut or between two cuts, eg in the production of wooden joints such as dovetails

- planeTo smooth with a sharp-bladed tool. - used to smooth the edge of a piece of timber by running a sharp blade in the direction of the grain, or can be used at an angle to produce a chamfered edge

- abradingTo create a good surface finish on the timber. or sandTo rub abrasive paper to improve a surface finish. - used to achieve a profiled shape or smooth surface finish by removing fine particles, normally the final stage in shaping the timber and done by hand or with a machine (belt, disc or orbital)

- hand sanding, using:

- abrasive paper such as sand or glass paper

- files

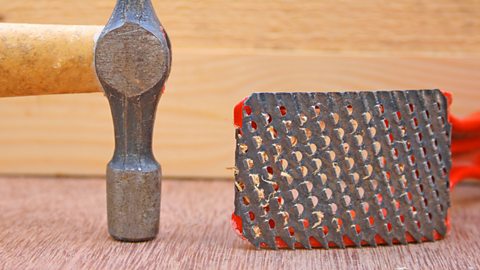

- raspUsed in abrading, similar to a file but with larger teeth that can leave marks in the wood. - have larger teeth than a file that can leave marks in the wood

- surformA tool that resembles a cheese grater, used to shave away a top layer of timber. - similar to a cheese grater in appearance, used for rough shaping but again leaves marks in the wood

Image caption, Rasps

Image caption, Surform

1 of 2

Turning

A latheA machine used to turn material so that it can be shaped to a cylindrical shape or bowl. works by spinning a piece of timber at speed. While the timber is turning, a wood-turning tool is pushed into the timber to change its shape. Some timber can be held in place by compressing it from end to end. This would allow a spindleA cylindrical-shaped piece of material. or cylinder to be shaped. Another way to hold the timber in place is to screw it to a faceplate - the timber then spins on the lathe, and this would allow a bowl to be turned.

Image caption, Turning a spindle on a lathe

Image caption, Timber screwed to a faceplate to turn a bowl

1 of 2

Carving

Wood carving uses chisels to cut away at the wood and produces a piece of artwork. It has been mostly replaced by CNC machinery because of its labour-intensive nature.