Production in quantity

There are many different processes used to cut and shape timbers in quantity:

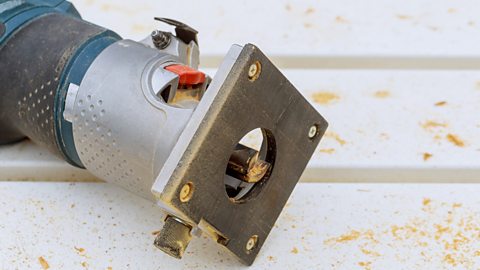

Routing

A router can be hand-held, mounted to a table or even computer controlled. All routers work by rotating a cutting bit at high speed. As the cutting tool passes over or along the edge of the timber, a cut or profiled shape is made. Routers can plunge into a material to cut holes. They can follow jigA tool used to aid the repetition of a process and/or to hold a work in place. or patternRepeated design or recurring sequence., for example kitchen fitters might follow a pattern to join worktops together.

Sawing

Sawing machines help cut timbers quickly. The circular saw and bandsawA saw with one long, toothed blade, mainly used for cutting timber and metal but can also be used to cut through large amounts of fabric. are commonly found in workshops.

Mortiser

A mortiser makes a square hole for a mortise and tenon joint.

Bag press

A bag pressA sealable bag that is often used to create curved shapes in laminated timber veneers. The bag is sealed and the air is sucked out while the glue dries between the veneers. A mould is used to help the timber take its shape. is often used to create curved shapes in laminated timber veneerA thin decorative covering of fine wood applied to a coarser wood or other material.. The bag is sealed and the air is sucked out while the glue dries between the veneers.

Scales of production

Manufacturing processes for different scales of production

There are four terms used to describe the scale of production in relation to manufacturing a product:

- prototypeThe first working model of a design used for testing, development and evaluation. or one-off production

- batch productionWhere one group of identical products is made at the same time, before moving onto producing the next group.

- mass productionWhen the same product is manufactured many times.

- continuous productionA production method that leads to many of the same product being made, continuously.

Prototypes and one-off production

There are many ways to produce a prototype - some are rough and look like models, and some function as intended and are well finished. Many architectural models are made from timber lolly sticks, matches or balsa wood. Model-making timber can be shaped easily and glued in place at speed.

A custom-made or bespoke product that is made from timber could be based on a customer design specificationDocument containing details of a product's required characteristics, and all the processes, materials and other information needed to design the product.. Products such as made-to-measure wardrobes or hand-crafted furniture are expensive because each piece of material has been designed and cut for that specific product, involving great skill and time.

Batch production

Batch production is where many items of the same product are produced. An example relating to timber is where a set of chairs is required to match a dining room set.

A carpenterA person that makes products from timber. could design the chair, and then cut all the timber at the same time to make the set. The carpenter would then have a kit to start making batches of chairs. If each part of the chair needed to be drilled in exactly the same place, the carpenter would make a drilling jigA tool used to aid the repetition of a process and/or to hold a work in place. that would hold the timber while each part was drilled. If a part of the chair needed the same shape profileThe outside edge of a shape. from a plank of timber, the carpenter would make a designing templateA form used to ensure other parts are made to match the form. so that each part would be shaped the same.

Each time a product is made, the materials that are used have had to be bought. If just one product is made, quite often the cost is high because small orders are placed to supply the materials. When a product is built on a large scale, money is saved when compared with the cost of making a one-off product.

Mass production

Mass-produced products are manufactured in large volumes, often on assembly line A series of workers and machines in a factory by which a succession of similar items is progressively assembled. where workers fit standard components such as screws and hinges to parts. Examples of mass-produced timber products are mouldingA piece of timber that has a decorative pattern along its length., doors and pencils.

Continuous production

Continuous production takes place 24 hours a day, 7 days a week and, in some cases, 365 days a year. There is not generally the demand for a timber-based product to be made using continuous production, but stock sizes of timber and paper can be produced using continuous production methods.

Techniques for quantity production

There are many techniques used for quantity production of timber to ensure that products are made efficiently and of a similar quality. For example, marking outMarks made on an item before cutting or forming. helps to ensure the timber is measured accurately and will be cut to the correct size repeatedly. Another example is the use of templateSomething that can be drawn around to mark a shape onto material, so that it can be cut or shaped repeatedly and accurately. made from card or thin sheet metal, which make cutting the same shape repeatedly quicker, more efficient and more accurate.

Marking out methods

Transferring measurements onto a material is especially important for one-off production. For batch and mass production the machinery is often set up to process the materials automatically.

In one-off production, it is important to start with a square edge so that the measurements can be made from these edges. This can be achieved using a set square.

Other aids include:

- jigs - used to guide a drill or saw to cut in exactly the same place each time on every piece of timber - reduces marking out time thus increasing the efficiency of the manufacturing process

- fixtures - holds the piece of timber in place whilst it is being worked on

- templates - made out of paper, card, thin metal or wood, these are drawn around to mark out the same shape repetitively, with the aim of speeding up the marking-out process and decreasing the chance of an error occurring

- patterns - a collection of templates that go together to make a part, or all, of a product

Sub-assembly

A sub-assembly is a series of components that, when assembled, form a part of a product. For example, a wooden knob turned on a wood lathe may be bought pre-made to add to a piece of furniture or to a door. This saves manufacture and assembly time and means that additional machinery, such as a lathe, does not have to be bought and operated.

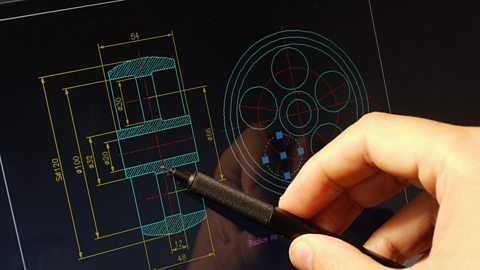

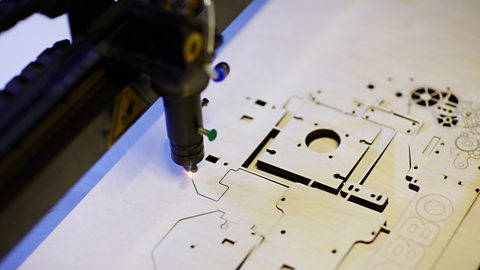

Computer aided manufacture (CAM)

A product can be drawn on a computer aided design (CAD)The process of creating a 2D or 3D design using computer software. package and then sent to a computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer. machine to be cut out, eg using a laser cutter. This has a high initial cost so is often used in mass production.

Image caption, CAD

Image caption, CAM - Laser cutter

1 of 2

Efficient cutting to minimise waste

Materials cost money so it is important to minimise waste. When marking out shapes on timber, it is important to make them as close together as possible to reduce any material waste.

Accuracy and quality control

When working with timber, it is important to remember that it is a natural material that changes shape as different amounts of water are absorbed by it. It can warp and twist at different times of the year depending on how dry or wet it is. For example, if a timber door for a shed is made to be a tight fit in the dry summer months, it is likely that the door will be too tight to open when it is wet or damp in the winter.

Working within a tolerance

When making something from timber, digital vernier caliperA digital device for measuring with accuracy. are often used to measure to 1/100th of 1 mm.

When working with timber, a tape measure can be used to measure a correct length to 1 mm. This toleranceThe amount by which a measurement can vary without affecting the ability of the product to be manufactured accurately. is acceptable due to the nature of the material and the fact that it will change shape at some point while being used.

Example

If a length of timber is measured with a tape measure, it could be written that the timber is 1,000mm +/- 1mm. This indicates that the timber could be 999 mm or 1,001 mm.

1,000 mm + 1 mm = 1,001 mm

1,000 mm - 1 mm = 999 mm

The range of possible sizes is anywhere between 999 mm and 1,001 mm. This means that some lengths might be 2 mm bigger than others.

If the tolerance was +/- 2 mm:

1,000 mm + 2 mm = 1,002 mm

1,000 mm - 2 mm = 998 mm

The range of possible sizes is anywhere between 998 mm and 1,002 mm and some lengths might be 4 mm bigger than others.

Question

A 1 m length of planed all round (PAR) ash needs to be cut with a tolerance of +/- 1%.

What would the range of tolerance be?

1 m = 1,000 mm

1% = 1,000 ÷ 100 = 10mm

Maximum length = 1,000 mm + 10 mm = 1,010 mm

Minimum length = 1,000 mm - 10 mm = 990 mm

Range of tolerance = 1,010 mm – 990 mm = 20 mm

(If worked in metres, the range of tolerance would be 0.02m)