Large-scale production processes

A commercial process is a method of manufacturing that takes place in industry. For timber this includes:

- sawing - using a circular or bandsawA saw with one long, toothed blade, mainly used for cutting timber and metal but can also be used to cut through large amounts of fabric.

- routingA process of using a rotary cutter to shape and cut material. - using a router

- turningA method of spinning a material so that a cylindrical shape or bowl can be produced. - using a lathe

- steam bending - using steam to bend solid wood

Sawing

Sawing machines help cut timbers quickly. The circular saw and bandsaw are commonly found in workshops.

Routing

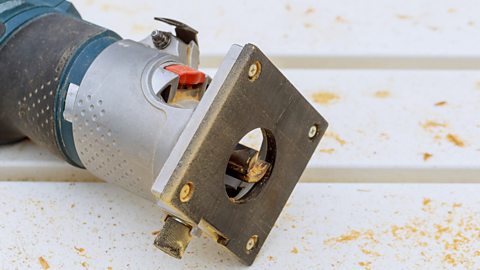

A router can be hand-held, mounted to a table or even computer controlled. All routers work by rotating a cutting bit at high speed. As the cutting tool passes over or along the edge of the timber, a cut or profiled shape is made. Routers can plunge into a material to cut holes. They can follow jigA tool used to aid the repetition of a process and/or to hold a work in place. or patternRepeated design or recurring sequence., for example kitchen fitters might follow a pattern to join worktops together.

Image caption, Hand-held router

Image caption, Table router

1 of 2

A hand-held routerA rotary cutter that is not fixed to a machine bed. A hand-held router can be used to cut and shape material. is either plunged down onto the timber or moved along an edge. A table routerAn inverted router that is fixed to a table. is fixed upside down so that the cutter protrudes from the table top. Both types of router produce the same effect. A computer controlled router, or computer numerical controlled (CNC) routerA method by a computer to execute a pre-programmed sequence. Machines move via numerical values along X, Y and Z axes., works by following a cutting path that has been designed on a computer. The material to be cut is fixed to a cutting bed so that the router is the only part that moves.

Turning

A lathe works by spinning a piece of timber at speed. While the timber is turning, a wood-turning tool is pushed into the timber to change its shape. Some timber can be held in place by compressing it from end to end. This would allow a spindleA cylindrical-shaped piece of material. or cylinder to be shaped. Another way to hold the timber in place is to screw it to a faceplate - the timber then spins on the lathe, and this would allow a bowl to be turned.

Image caption, Turning a spindle on a lathe

Image caption, Timber screwed to a faceplate to turn a bowl

1 of 2

Steam bending

Steam bending is a traditional method of shaping and bending wood. Strips of wood are placed in a watertight chamber and steam is pumped in, softening the fibres within the wood and allowing it to be bent. Then the bent wood needs to be clamped in a mouldA hollow container used to give shape to molten materials. until the wood dries sufficiently for it to hold its new shape. This method of producing shaped timber allows for the natural strength of timber to be used as a structural property of the final product.