Shaping

Most materials need specialist tools and equipment to shape and form them - polymers are no exception because of the unique propertiesThe mechanical, physical or optical properties of materials that define how they behave in use. they generally possess.

When marking out on the surface of a polymer, especially on a sheet of acrylic, a 'chinagraph' pencilA wax or grease-based pencil that can write on most non-porous surfaces. is used as this will mark on the high-glossyShiny. surface. If no such pencil is available, an alcohol-based permanent marker would also work to mark a line to cut to.

Polymers that are cut by hand are usually done by a coping saw, or sometimes a hacksawA common tool used for cutting metals and polymers. - if it is a smaller piece of polymer then a junior hacksaw can be used. Once the polymer is cut close to a marked line, a fileA common tool used for finishing and shaping. can be used to remove up to the desired line. Files can be bought in different shapes, sizes and cutting grades - a rough-cut file can remove polymers faster than a smooth file and should always be used first.

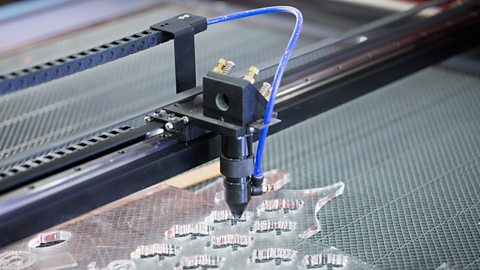

Laser cutter

A laser cutterA machine that uses a laser beam to vaporise material and cut out shapes very accurately. is an example of computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer. and is able to accurately engrave and cut a range of sheet materials, including acrylic. The edge of a material cut on a laser cutter requires no finishing, unlike hand cut materials, so it can save time.

It is very often the case that the polymer, for example acrylic, needs to be bent to a shape. Once the acrylic is cut, either by hand or using a laser cutterA machine that uses a laser beam to vaporise material and cut out shapes very accurately., it can be bent using a strip heat, often called a line benderA machine with a heated element, used to heat and shape polymers..

Acrylic needs to be heated to around 150 to 170°C to bend without cracking, and jigA tool used to aid the repetition of a process and/or to hold a work in place. can be made in a variety of ways so that the bend produced remains the same as the acrylic cools.

vacuum formerA machine that heats a polymer so that it is malleable enough to be pulled over a former with a vacuum. can be used for making mouldA hollow container used to give shape to molten materials. and housingAn exterior case or enclosure. for electronic products. high impact polystyrene (HIPS)A tough, rigid plastic material with high impact strength. is often the material used in a vacuum former, as it heats up quickly depending on thickness. The process is as follows:

- the HIPS is heated

- once hot, the solid formerA solid shape that is often used to make a mould. is pressed into the HIPS from a bed that can rise

- the vacuum is turned on, removing all the air from around the former

- the HIPS takes the form of the solid former

Sometimes talcA clay mineral. can be dusted on the former so that it drops out of the mould with ease. A good vacuum-formed mould will only be possible if a good former has first been made. The former must have a draft angleA tapered angle on a former., so it doesn’t get stuck in the mould.

Polymers can also be shaped, once hot, by press mouldingA method of pressing a hot polymer over a former. and drape formingA method of draping a hot polymer over a former to produce a curved shape. - methods often used to shape acrylic. Once the acrylic is hot and malleableCapable of being hammered or pressed into a new shape without being likely to break or return to the original shape., it can be pressed over a former to take a new shape.

Since polymerA polymer is a large molecule formed from many identical smaller molecules (monomers). Polymers can be natural or synthetic. Plastics are long chains of polymers. have a relatively low melting point, they can be shaped easily once moltenA term used to describe a liquid substance (eg rock, glass or metal) formed by heating a solid. by either injection mouldingMolten material forced into a mould. or extrusionA material is pushed through a die so that the cross section remains the same for the length of the material..

Injection moulding

Injection moulding is used in industry to produce most mass productionWhen the same product is manufactured many times. polymer parts using the following process:

- granular plastic is held in a hopper

- it is moved via an Archimedean screwA spiral rotating in a tube to push material in one direction. along a heated tube, called the heating chamber

- once the polymer has been melted, it is pushed into a mould with a hydraulic ramA pump operated by the displacement of water (in some cases oil) that is used to give unidirectional force. - the use of the hydraulic ram ensures just enough material is injected into the mould each time

- the mould is then cooled so that the moulded plastic can be removed

Image caption, 1.

Image caption, 2.

Image caption, 3.

Image caption, 4.

1 of 4

Extrusion

Extrusion works in a very similar way to injection moulding:

- granular plastic is held in a hopper

- it is moved by Archimedean screw along a heated tube, called the heating chamber

- once the polymer has been melted it is pushed through a die mould, which will form the shape of the extrusion

- because there is no hydraulic ram in this process, molten plastic can be fed through the die continuously

Common extruded polymer products are plastic pipes, tubes and guttering.