Fabricating and assembly

Careful consideration needs to be taken of how a paper or board product will be joined or assembled during manufacture. If it is a permanent join, for example, would glue be suitable? Or do the pieces need to move?

Papers and boards will often need strengthening and there are a variety of ways of doing this, for example:

- laminatingBonding layers of material together to improve strength., which consists of layering different materials together, eg drinks cartons

- aluminium can be used as an insulator or bacterial barrier, eg in food packaging

- ribA raised piece added to material for strength and support. can be added, eg corrugated board has ribs in the form of crimps

By adding dissimilar materials, such as a transparent window to an envelope, a designer may find they have to consider how the different materials fold, bend or fix to each other.

marking outMarks made on an item before cutting or forming., using tools such as French curves or set squares, requires skill and accuracy for a professional finish.

Image caption, Ruler, protractor and set square

Image caption, French curves

1 of 2

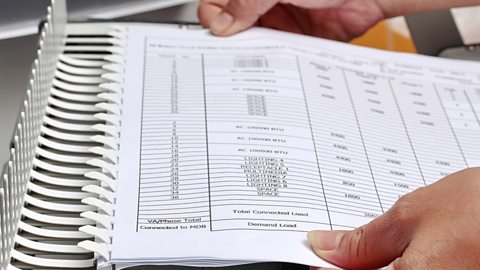

When a book or pamphlet is bindingA finishing process to join pages together to form a book., care should be taken that it opens fully without any pages falling out. Hand stitching is a skilled and time-consuming process, but comb binding machines are readily available in offices or libraries. A professional bookbinding service could offer an effective but more costly alternative to comb binding.

Temporary or removable components

| Component | Properties | Use |

| Split pin | Easy to apply, reusable, cheap | Creating a fixed or movable pivot for shop displays or models |

| Mapping pins | Easy to apply, reusable, cheap | Temporarily holding card or paper in place |

| Stapling | U-shaped wire is driven into paper or card with a stapler, easy to use, readily available, hard to staple thick materials | Attaching paper together or constructing cardboard boxes |

| Taping | Thin layer of adhesive on a plastic film, lots of types available, most are difficult to remove apart from masking tape | Joining paper and card, eg on the spine of a book |

| Adhesives | Wide variety of options including PVA , glue sticks, hot glue | Sticking a variety of objects onto paper and board |

| Paper engineering | Requires skill and practice to manipulate paper | Making pop-up 3D cards and scenes |

| Component | Split pin |

|---|---|

| Properties | Easy to apply, reusable, cheap |

| Use | Creating a fixed or movable pivot for shop displays or models |

| Component | Mapping pins |

|---|---|

| Properties | Easy to apply, reusable, cheap |

| Use | Temporarily holding card or paper in place |

| Component | Stapling |

|---|---|

| Properties | U-shaped wire is driven into paper or card with a stapler, easy to use, readily available, hard to staple thick materials |

| Use | Attaching paper together or constructing cardboard boxes |

| Component | Taping |

|---|---|

| Properties | Thin layer of adhesive on a plastic film, lots of types available, most are difficult to remove apart from masking tape |

| Use | Joining paper and card, eg on the spine of a book |

| Component | Adhesives |

|---|---|

| Properties | Wide variety of options including PVA , glue sticks, hot glue |

| Use | Sticking a variety of objects onto paper and board |

| Component | Paper engineering |

|---|---|

| Properties | Requires skill and practice to manipulate paper |

| Use | Making pop-up 3D cards and scenes |