Properties

There are many commercialAssociated with business and profit. products used on a daily basis that are made from plastic polymerA polymer is a large molecule formed from many identical smaller molecules (monomers). Polymers can be natural or synthetic. Plastics are long chains of polymers..

injection mouldingMolten material forced into a mould. plastic seating can be made from a variety of different polymers. A popular chair, called the ‘polyside’ chair, was designed by Robin Day and launched in 1963. It was the first to be injection moulded from a single piece of polypropylenePolymerisation from the monomer propylene. and is a design icon, having been copied in many forms since. It is still in production in some form today.

When making chairs, a polymer is a good choice of material:

- they can be injection moulded in mass

- the colours can be changed

- the identically duplicated shape means the chairs can often be stacked

- they are light in weight

- they are easy to clean

Electrical plugs and sockets are made from compression mouldingA process where thermosetting polymers are set or cured under heat and pressure. They may be placed in the mould as a powder or injected as a liquid. polymers, specifically from a thermosettingAlso called ‘thermoset’. Can only be formed once as it cannot be reheated and therefore cannot be recycled. polymer called urea formaldehydeA thermosetting polymer.:

- it can be compression moulded in mass

- it is an excellent insulator to electricity

- it absorbs very little water

- it has a hard outer, high-gloss finish

- it is resistant to heat

Urea formaldehyde is also used as the adhesive to band particles together when medium-density fibreboard (MDF)A type of engineered wood made of compressed wood and fibre particles held together with glue. is made.

Most polymers are formed by processing crude oilMixture of hydrocarbons, mainly alkanes, formed over millions of years from the remains of ancient dead marine organisms.. thermoformingAlso called ‘thermoplastic’. Can be reformed when heated, and therefore can often be recycled. polymers can be heated and formed repeatedly. They are pliableFlexible and easy to bend. and recyclableThe ability to process into something else.. Thermosetting polymers are brittleIf something is brittle it is easily broken. and can only be formed once. They are hard to recycle. They are good insulatorMaterial that is a poor conductor of electricity or heat. and are resistant to heat and chemicals.

There are a wide range of thermoforming polymers with varying properties and uses. Commonly used thermoforming polymers in schools and industry include:

- acrylic

- high impact polystyrene (HIPS)A tough, rigid plastic material with high impact strength.

- polyvinyl chloride (PVC)

- Styrofoam

Other commonly used thermoforming polymers in industry include:

- rigid polystyrene

- expanded polystyrene

- acrylonitrile butadiene styrene (ABS)

- polyethylene terephthalate (PET)

- polyurethane

Polyvinyl chloride (PVC)

PVC is available in sheet form or granuleA small compact substance., making it suitable for vacuum forming Warmed sheet plastic is sucked against a mould to give it shape. or injection mouldingMolten material forced into a mould.. It is chemical and water resistant and is commonly used in blister packs, plastic toys and window frames.

Image caption, Blister packs

Image caption, Children’s plastic building blocks

Image caption, PVC window frame

1 of 3

Polystyrene

Styrofoam is an extrusionA material is pushed through a die so that the cross section remains the same for the length of the material.polystyreneA man-made material made from processed crude oil. available in sheetA way to describe that a material is normally much thinner than it is long or wide. form. It is lightweight and an excellent insulator. It is commonly used to make models as it can be quickly and easily shaped using hand tools, eg a hot wire cutterA tool used for shaping polystyrene foam. ; however, the fumes given off are unpleasant and it should be cut in a well-ventilated space.

Polystyrene is available in two forms:

- Rigid - A commonly used rigid form of polystyrene is high impact polystyrene (HIPS), available in granule and sheet form. The sheet form of HIPS is used for vacuum forming. HIPS is safe to use with food products and lightweight, and as such is used commercially to package food products, eg yoghurts.

- Expanded - Available in sheets and balls, it is a good insulator, impact resistant and lightweight. Expanded polystyrene balls can be used to fill stuffed toys, while sheets are used in packaging to protecting electrical products.

Acrylonitrile butadiene styrene (ABS)

ABS is commonly available in sheet and granule form. It is used in car bumpers and hard hats as it is lightweight, durable, hard and is able to absorb impact.

Polyethylene terephthalate (PET)

PET is available in granule and sheet form and is lightweight, strong and safe to use with food products. It is used in food packaging and is a common replacement for glass bottles as it is transparent but will not shatter if dropped.

Polyurethane

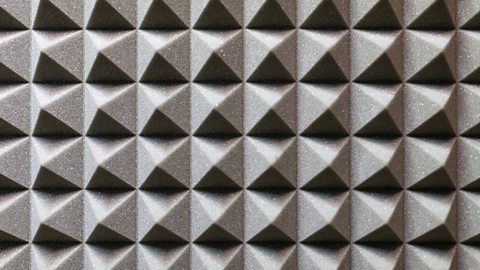

Polyurethane is available in liquid, granule, foamA material formed by trapping air within a solid. and sheet form. It is flexible, hardwearing and able to hold weight without ripping. It is used to make carrier bags or, when in foam form, for soundproofing.