Digital design tools

As a result of advances in technology, it is common practice for digital technology to be used to aid the design, development and manufacturing of components and products. Digital design tools include:

- computer aided engineering (CAE)Used to test a computer aided design (CAD) through computer simulations, providing data to be analysed by designers.

- computer aided design (CAD)The process of creating a 2D or 3D design using computer software.

- computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer.

A design could start as a set of 2D sketches then evolve into a 3D CAD drawing of the part. Computer aided manufacture, eg using 3D printing, can quickly allow it to be tested, evaluated and then finally machined using computer numerical controlled (CNC) machinery, eg a CNC milling machine.

Image caption, Initial sketches

Image caption, An example of computer aided design (CAD)

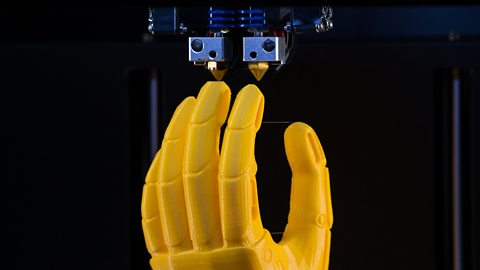

Image caption, 3D printing

Image caption, A computer numerical controlled (CNC) milling machine

1 of 4

Computer aided engineering (CAE)

Computer aided engineering (CAE) enables a designer to test and analyse the performance of a component or design through the use of computer simulation software. The use of CAE offers greater analytical capabilities in comparison to traditional testing, including:

- decreasing the lead timeThe time between the start of a project and the final product being manufactured. of a product

- enabling different materials to be tested for suitability

- reducing the cost of development

- decreasing development time as data can be analysed quickly

- allowing improvements to be made quickly as the files are digital

Computer aided design (CAD)

Computer aided design (CAD) software is a common feature of an iterative design A cyclic design process of modelling and testing to achieve gradual improvements to the design. process, allowing designers to create designs digitally in either 2D or 3D form. This can then be edited and manipulated quickly and can be exported to be used in computer aided manufacture (CAM). For fabrics, examples of CAD use include:

- image creation and manipulation software - the use of digital technology to design and manipulate image work that will be used in printing onto fabrics

- digitallay planningPositioning pattern pieces onto fabric in the most economical way, minimising fabric wastage. - the careful preparation by computer technology of all parts of a product being laid out on the fabric to help manage material, space and labour

Computer aided manufacture (CAM)

A product can be designed on a cmputer aided design (CAD) package and then sent to a computer aided manufacture (CAM) machine to be cut out, eg a laser cutter. This can have a high initial cost so is often used in mass production or to create rapid prototypeThe first working model of a design used for testing, development and evaluation. at the start of a design process to save time and money.

Examples of CAM machinery include:

- laser cutter - some fabrics can be cut or etched using a laser that passes through a small diamond, which focuses the laser beam and intensifies its power so that it can burn through material and cut out 2D shapes

- computer numerical controlled (CNC)The use of computers to control cutting and shaping machines and a key computer aided manufacture (CAM) technique.sewing machines - controlled by the use of computer technology, the machine will follow a CAD template created by programming the stitching of the machine

- 3D printing - layers of approximately 0.3 mm of extrudedShaped by being forced through an opening. material, commonly plastic but also metals such as aluminium, titanium and steel, are built up into a 3D solid and can be used to prototype fastenings or in combination with fabrics as fashion wear

- printing - printing patterns onto the top surface of fabrics in a variety of ways:

- sublimation printing uses sublimation inkA dye suspended in a liquid for printing on to hard surfaces. to print onto coated paper, transferring an image onto the fabrics once heated

- digital printing allows fabric to be printed on directly from an inkjet head and is expensive but offers a wide range of colours.

- weaving - large, automated industrial loomMachine for weaving threads. are controlled by computer aided design (CAD) software that allows colour schemes and weave patternThe pattern made when weaving threads in different colours or styles. to be controlled.

Image caption, Digital printing on a fabric

Image caption, Automated industrial loom

1 of 2