Fabricating and assembly

When joining fabric together it is important to consider the overall appearance of the product to produce a professional finish. There are a variety of seamA seam is usually 1.5 cm wide and is produced by sewing two pieces of fabric together. that can be used to achieve this:

- plain seam - commonly used and gives a flat result; used on non-fraying and thick fabrics

- overlocked seam - neatening seams to prevent fraying can be completed by adding a line of zigzag stitch or by using an overlockerA multi-threaded machine that is often used to enclose a seam when making clothes. for a professional finish, which sews and trims in one process

- French seam - a strong but bulky seam used on fine fabrics, underwear and children’s clothes as the raw edges are concealed

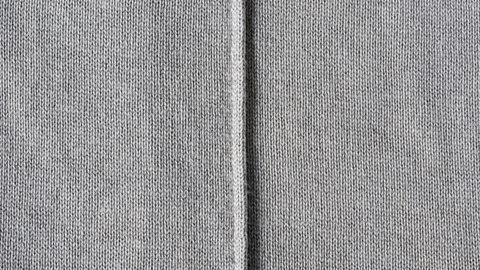

- flat felled seam - strong but bulky and visible

- bound seam - uses bias bindingA tape that is stitched along edges of quilts to finish the cut edge. to neaten and encase the raw edge of the fabric

Image caption, Plain seam

Image caption, Overlocked seam

Image caption, Flat felled seam

Image caption, French seam

Image caption, Bias bound seam

1 of 5

Hems can also be used to produce a professional finish:

- blind hem - the fabric is folded over and attached with tiny stitches by a special presser foot; invisible stitching can be used if hemming by hand

- rolled hem - narrow hems used on fine, delicate fabrics such as chiffon

Fusing

When manufacturing waterproof products, such as jackets or tents, it is important to use methods of finishing that cover the seam and do not create holes. seam tapeA tape that can be fixed to a seam, sometimes by heat, so that the seam is strengthened and sometimes made to be waterproof. and heat fusingA method of joining fabric with heat. is used to produce a waterproof sealed seam. Each time fabric is stitched, a needle makes a small hole. If the product needs to be waterproof, a series of these holes would let water though. When a tent is made, for example, it is stitched together and then each seam is covered with a tape that is fused to the seam by heat. This heat fusing method ‘welds’ the tape on top of the seam and ensures that the stitch holes are covered.