Techniques for quality production

When a product is going to be mass productionWhen the same product is manufactured many times., it can cost a manufacturerA person or company that makes something from raw materials or from an assembly of component parts. less money in the long term to invest in specialist equipment and processes, as these will ensure a higher-quality product and a quicker production process.

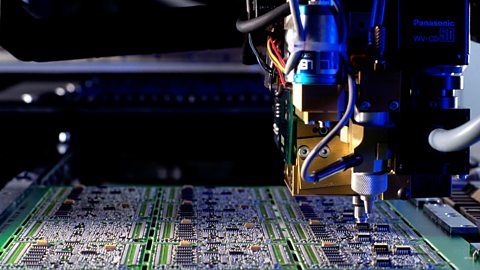

Pick and place assembly

pick and place assembly A robotic machine that is programmed to pick and place electrical components so they can be placed in the correct place on a circuit board. is when componentA part that when put together makes a product. are picked up and placed on a circuit board automatically by robots, with suction cups used to pick up and arrange components in the right place on the circuit board A copper sheet used to attach electrical components. . It is used in the production of printed circuit boards (PCBs) in electrical systems. Although buying the machines and programming them is expensive and time-consuming, their performance is quick and accurate, and it is also cost-effective when mass producing a circuit.

Manual assembly

Manual assembly of components can be fiddly and time-consuming, as components are small and take longer to fit into place when done by hand. This assembly method is used mainly for circuits made up of components that are fitted with pinThe pins on an integrated circuit appear in two rows and are manufactured as dual in line (DIL) packages. through a circuit board. This is a costly and slow method of production, more suitable for specialist production of small numbers of electronics such as for TVs, radios and alarms.

Flow soldering

flow soldering A solder paste is used to fix components in place until heated. The solder will only attach to an electrical pad because the rest of the board will be covered in lacquer. is a technique used to attach components to a circuit board quickly, without the need for human input. This improves accuracy and speed and reduces the amount of solder used. To allow components to be added to several circuit boards in a row, surface mounted technology (SMT) Components that can be soldered directly to a board rather than having to be pushed through a hole. is used. This allows connections to be made easily while taking up as little room as possible. Once the SMT components are placed on the PCB with pre-soldered pasted pads, they are put into a precisely controlled oven where the solder melts into the correct positions and creates an accurate connection.

Wave soldering

wave soldering A molten flow of solder is used to fix components in place. The solder will only attach to an electrical pad because the rest of the board will be covered in lacquer. is used in the mass production of PCBs as it is a fast, efficient and accurate way of soldering PCBs. Components are placed into a PCB by their pins through pre-drilled holes and put on a conveyor belt Used on a production line to move items along. - this takes the boards through a series of stages:

- flux Chemical used to improve the flow of solder. is added to the underside board to help the flow of solder

- it is then heated up and passed over a wave of solder

- the solder covers the pins under the PCB and creates a bond once cooled

Accuracy

When creating electrical or mechanical products, the accuracy of production is vital. If one part of the process is poorly fitted or too big, the products will not function and could become dangerous to the user. How accurate a product needs to be is described as the toleranceThe amount by which a measurement can vary without affecting the ability of the product to be manufactured accurately..

Poorly fitting mechanical parts will perform badly and are likely to have a very small tolerance measurement. For example, chains or gearA wheel with teeth that can change the speed of a mechanism. that are slightly bigger or smaller than necessary will be prone to jamming and breaking.

Printed circuit boards (PCBs) need to be so accurate that any tolerance measurements are likely to only be +/- 1 mm, to stop any materials touching and causing circuits to stop working.

resistorAn electrical component that restricts the flow of electrical charge. Fixed-value resistors do not change their resistance, but with variable resistors it is possible to vary the resistance. used in electrical circuits have a tolerance relating to the amount of power they allow into a circuit. The smaller that tolerance is, the less likely the circuit is to be overloaded and damaged, but the more expensive the resistor will be. The amount of tolerance a resistor has is shown with the colour of the fourth stripe down and is usually silver or gold

Example

A resistor has a value of 1,500 Ω and has a tolerance of +/- 10 per cent.

1,500 × 0.1 = 150

Range of tolerance = 150 Ω either side of the 1,500 Ω mark.

1,500 Ω + 150 Ω = 1,350 Ω minimum

1,500 Ω - 150 Ω = 1,650 Ω maximum

Question

A resistor with a value of 22,000 Ω has a tolerance of +/- 5 per cent. What are the minimum and maximum values for this resistor?

22,000 × 0.05 = 1,100 either side of the 22,000 Ω mark.

22,000 - 1,100 = 20,900 Ω minimum

22,000 + 1,100 = 23,100 Ω maximum

Quality control

During the manufacturing process, quality control (QC)A set of checks intended to ensure that a product will meet the specified customer requirements once it has been manufactured. These procedures are followed before work is complete, as opposed to afterwards. checks are carried out. These can check whether:

- PCBs are cut accurately

- components are attached securely

- casings are attached securely

- edges on castings are trimmed and neat

Although quality control checks can increase waste with faulty products being thrown away, if a factory develops a reputation for being reliably high in quality, money is saved in the long term through products being reordered.