CAM and lasers

computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer. is central to many production systems, enabling a large range of processes to be carried out using technology. computer numerical controlled (CNC)The use of computers to control cutting and shaping machines and a key computer aided manufacture (CAM) technique. machines incorporate high-spec precision from a computer aided design (CAD)The process of creating a 2D or 3D design using computer software. to manufacture a product. CNC can produce products by turningA method of spinning a material so that a cylindrical shape or bowl can be produced., millingThe process of using a machine with a rotary cutter to cut and shape material. or routingA process of using a rotary cutter to shape and cut material.. It can also be utilised to cut, engrave, heat cut and even print in solid materials.

Image caption, CNC milling

Image caption, CNC turning

1 of 2

| Advantages of CAM | Disadvantages of CAM |

| Fast | High initial cost |

| Accurate | Maintenance of machines is required |

| Can be repeated easily | Workers need training |

| Less labour intensive | Less workforce is needed |

| Fewer errors |

| Advantages of CAM | Fast |

|---|---|

| Disadvantages of CAM | High initial cost |

| Advantages of CAM | Accurate |

|---|---|

| Disadvantages of CAM | Maintenance of machines is required |

| Advantages of CAM | Can be repeated easily |

|---|---|

| Disadvantages of CAM | Workers need training |

| Advantages of CAM | Less labour intensive |

|---|---|

| Disadvantages of CAM | Less workforce is needed |

| Advantages of CAM | Fewer errors |

|---|---|

| Disadvantages of CAM |

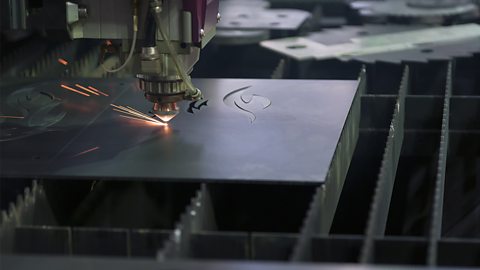

Laser cutter

A laser cutterA machine that uses a laser beam to vaporise material and cut out shapes very accurately. is a high-precision CAM machine that cuts a wide variety of materials using an extremely powerful laserAn intense beam of light that is monochromatic and coherent (in phase). beam directed onto the material using angled mirrors. The power setting can be varied - if the power is reduced or the speed is too high, then the laser beam will not cut completely through the material and will engrave it instead.

Timber and polymers can often be cut easily using a laser cutter - it is possible to cut other materials such as glass and metal, but the power of the laser will need to be higher. The process enables rapid prototyping and reduces material wastage, therefore reducing costs. It achieves cleaner edges compared with other CNC processes, and can be repeated with very little set up cost.