Large-scale production processes

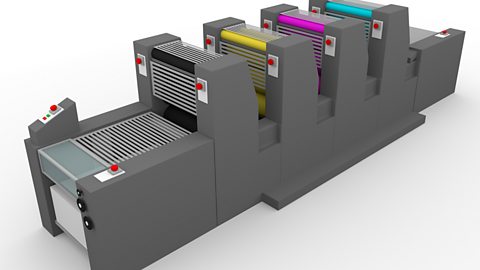

The main commercial printing process for paper and boards is offset lithographyA commercial printing method that uses four colours, cyan, magenta, yellow and black (CMYK).. This is a common process used in printing as it is suitable for large print runs and gives a high-quality print to a consistent standard. Offset lithography prints small dots in four main colours that overlay each other to create the full colour spectrumThe colours that are visible to the human eye.. Ink is transferred (offsetThe way ink is transferred from a plate.) from a metal plate to a rubber roller, and the paper or card never comes into contact with the image on the plate.

The four colours are printed to check the alignment of the printer by producing what is known as a registration markA registration mark is a circular pattern that is printed using all four colours. When all four colours overlap they produce a black circle. If the alignment of a colour is out, the colour will show.. The four colours are cyan, magenta, yellow and black (CMYK). CMYK is a colour modelThe way colour information is stored. The two main models are RGB (red, green, blue) and CMYK (cyan, magenta, yellow, key/black)., where cyan (C) is blue, magenta (M) is red, (Y) is yellow and (K) is key. The term ‘key’ is used rather than black because the three printing plates, C, M and Y are all ‘keyed’ and aligned with the black plate.

Once printing has taken place, the paper or card needs to be cut to size and sometimes folded. die cutA method cutting paper or card by pushing a blade through the material. is a commercial process that accurately cuts and creaseA fold usually found on paper, card or cloth. paper or card at speed. Within a die cutter, sharp blades are arranged to produce a cut, while rounded blades are arranged to produce a crease - this allows for the material to be folded rather than cut.

The arrangement of sharp and rounded blades produces a netA net of a solid shape is a flat shape which can be cut out and folded to make the solid shape. as the card is stamped by the die cutter. Some die cutters can be found in schools, and these smaller versions produce one net at a time. Commercial die cutters are often on a roller and cut the card as the roller passes over the material.

Screen printing

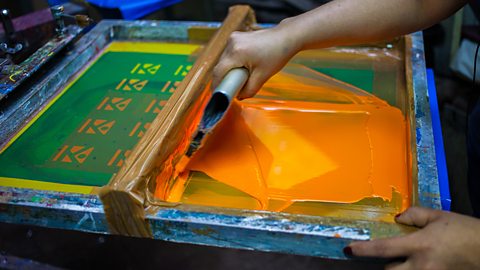

Screen printing is used for small quantity print runs for items such as posters and wallpapers. A pattern is printed onto fabric through a stencil, held in place by a screen. Each screen prints one part of the design in one colour. After printing, the dye must be fixed using steam or dry heat.

Image caption, Mesh is stapled to a frame to make a screen and masking tape is stuck to the underside of the screen

Image caption, A stencil is made from paper and placed under the screen but on top of the paper

Image caption, Ink is poured at one end of the screen and pressed down and drawn across

Image caption, The screen is carefully lifted and the print is checked before the process is repeated it using a squeegee

1 of 4

Digital printing

Digital printing, eg using inkjet and laser printers, is one of the widest used printing processes and is commonly available. It is suitable for small quantity print runs in schools, offices and homes.

Image caption, Inkjet printer

Image caption, Laser printer

1 of 2

Vinyl cutting

A vinyl cutterA CNC machine used to cut vinyl sheet., also known as a plotter, is a computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer. machine for cutting vinyl graphics and is often used for graphics and company information on vehicles. The material cut is sticky on one side, enabling it to be stuck to a surface with ease. The main stages of the process are:

- graphics are designed on computer in a 2D format

- the file is sent to the vinyl cutter, which moves a cutting blade on the surface of the vinyl to cut out shapes

- waste vinyl is removed by hand

- remaining vinyl graphics are peeled from the backing material using transfer film

- vinyl graphics are stuck to the desired surface such as a board or hard surface

Image caption, Vinyl being cut

Image caption, A common example of vinyl use

1 of 2