Commercial processes

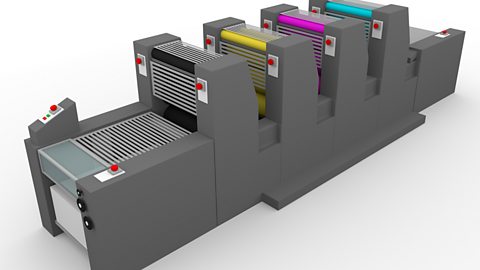

The main commercial printing process for paper and boards is offset lithographyA commercial printing method that uses four colours, cyan, magenta, yellow and black (CMYK).. This is a common process used in printing as it is suitable for large print runs and gives a high-quality print to a consistent standard. Offset lithography prints small dots in four main colours that overlay each other to create the full colour spectrumThe colours that are visible to the human eye.. Ink is transferred (offsetThe way ink is transferred from a plate.) from a metal plate to a rubber roller, and the paper or card never comes into contact with the image on the plate.

The four colours are printed to check the alignment of the printer by producing what is known as a registration markA registration mark is a circular pattern that is printed using all four colours. When all four colours overlap they produce a black circle. If the alignment of a colour is out, the colour will show.. The four colours are cyan, magenta, yellow and black (CMYK). CMYK is a colour modelThe way colour information is stored. The two main models are RGB (red, green, blue) and CMYK (cyan, magenta, yellow, key/black)., where cyan (C) is blue, magenta (M) is red, (Y) is yellow and (K) is key. The term ‘key’ is used rather than black because the three printing plates, C, M and Y are all ‘keyed’ and aligned with the black plate.

Once printing has taken place, the paper or card needs to be cut to size and sometimes folded. die cutA method cutting paper or card by pushing a blade through the material. is a commercial process that accurately cuts and creaseA fold usually found on paper, card or cloth. paper or card at speed. Within a die cutter, sharp blades are arranged to produce a cut, while rounded blades are arranged to produce a crease - this allows for the material to be folded rather than cut.

The arrangement of sharp and rounded blades produces a netA net of a solid shape is a flat shape which can be cut out and folded to make the solid shape. as the card is stamped by the die cutter. Some die cutters can be found in schools, and these smaller versions produce one net at a time. Commercial die cutters are often on a roller and cut the card as the roller passes over the material.