Tools, equipment and processes

Production aids

A designing templateA form used to ensure other parts are made to match the form. can be used to help ensure that information is placed correctly. They are used to ensure the shape of your design is accurate and can be used repeatedly to ensure the same shape is produced each time. They can be drawn around or inside to help ensure that sketches are identical and that particular shapes are drawn as desired, such as a cricle or ellipse template. Other kinds of templates can be held up against a product to check the shape after manufacture.

A patternRepeated design or recurring sequence. is often used in the commercial manufacture of paper and boards. Patterns can be created by hand, but it is quicker and easier to use computer aided design (CAD)The process of creating a 2D or 3D design using computer software., and it can be more consistent. Wallpaper is a great example of the use of a pattern.

Measuring

There is a range of measuring equipment available to aid accurate drawing:

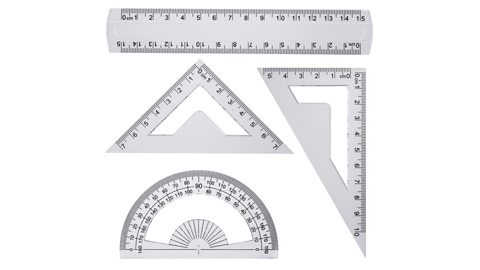

- a ruler - to measure distance and draw a straight line

- a protractor - to measure angles

- a set square - to draw lines at specific angles

- French curves - to draw curves of different sizes

Image caption, Ruler, protractor and set square

Image caption, French curves

1 of 2

Cutting

A range of tools can be used to cut paper or board accurately:

- guillotine (paper trimmer) - to cut a large number of paper sheets at once with a straight edge

- craft knife - to cut and score paper and cardboard, particularly useful when cutting internal shapes out of material

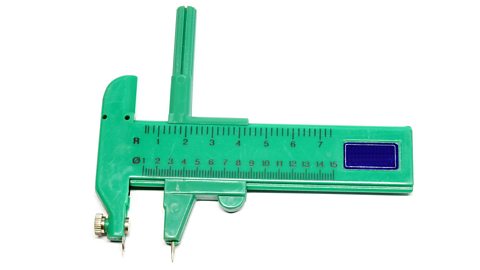

- compass cutter - to cut a circle or an arcA portion of the circumference of a circle. from paper or thin card

- rotary cutter - to cut a circle or an arc from thicker cardboard

- die cutter - to cut, creaseA fold usually found on paper, card or cloth. and perforatePressing small holes into a material. paper and card at high speed and accuracy

- laser cutter - to perform the perfect intricateFine detail. cut to paper and card, if the speed and power are set correctly

Image caption, Compass cutter

Image caption, Die cutter

1 of 2

Coatings and surface alterations

Paper and board can be protected further by laminating, which gives a shiny, water-resistant surface. It creates a thick, durabilityThe ability of a material to withstand wear, especially as a result of weathering. surface, often making the paper or board last longer. The paper or board is placed in a plastic sleeve, which is then heated and pulled through rollers, bonding the two surfaces of the film together and sealing the product.

Quite often paper and card are modified by the addition of chemicals or processes. Bleach is added to make the paper or card whiter, and varying amounts of bleach can be added so that the paper or card is the required colour.

Some papers are suitable for use with markers, as these papers do not allow the ink to bleed when they get wet from the marker ink. sizingThe addition of chemicals that are applied to paper to make the paper resistant to liquid. is the term used when a chemical is added to the paper to give it a protective glaze. This glaze prevents the paper from being absorbentAn ability to hold a liquid. and makes it suitable for use with wet marker pens.

There are many other additions that can change the working propertiesHow materials behave in different environments when subjected to changing conditions, eg force or temperature changes. of the material. Clay can be added to card to make a paper plate, or a clear ultraviolet (UV)Ultraviolet light is a form of radiation that can come from the Sun, or is artificially produced by ultraviolet lamps and bulbs. sensitive liquid can be applied to card to give a high-gloss finish. A UV glossy coating is better for the environment as there is no laminated polymer to separate during the recycling process.