Papers and boards

Types of papers and boards and their uses

Selecting materials

Materials can be selected based on their working propertiesHow materials behave in different environments when subjected to changing conditions, eg force or temperature changes.. It is important to know and understand which materials can be used for a specific purpose:

- How do they look?

- What are they commonly used for?

- How can they be manufactured?

- How do they perform in use?

- What makes them unique - are they the most durableHardwearing., the lightest etc?

Paper and boards should be selected based on the purpose for which they will be used. This could include:

- packaging

- drawing and sketching

- model making

- point of sale displays

- promotional material

Different factors affect material selection such as:

- how easy it is to recycleTo break down and process so a new material is produced - one of the 6 Rs.

- how expensive it is

- what it will be used for

- if it has any special properties, eg better for printing, rigidityResistance to bending., transparentAble to be seen through., folding, gluing, easily strengthened etc

- how easily it can be joined or fixed together

Papers and boards have been developed for a lot of different purposes. Paper and board can be:

- textured

- embossedTo stamp a pattern onto a surface so that it stands out.

- printed on

- laminatedAt least two layers of material bonded together. with other materials to make them waterproof, eg drinks cartons

Image caption, Textured

Image caption, Embossed

Image caption, Laminated

Image caption, Printed

1 of 4

Printing process procedures

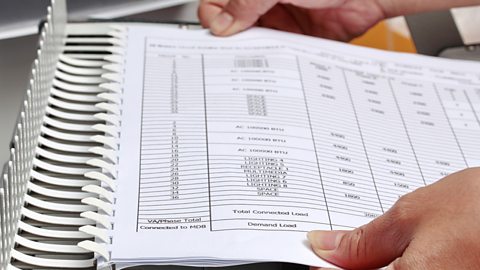

When manufacturing products in bulk, such as books, magazines, leaflets, packaging and other printed products, there are three processes to follow:

- pre-press

- on-press - also called ‘press’

- finishing - also called ‘post-press’

Pre-press

This process includes preparing digital files for a printing press - from the creation of a print layout and checking the artwork on the computer, to making the separate colour plates ready for the final printing.

On-press

This is the stage in the printing process where the preparing, positioning and loading of paper or board happens and the actual printing of the artwork occurs.

Finishing

This is the final part after the product has been printed. It is given a finish such as die cutA method cutting paper or card by pushing a blade through the material., embossedTo stamp a pattern onto a surface so that it stands out., foil stampingCommercial printing process applying a metallic foil onto a solid surface using heat and dyes. , laminatingBonding layers of material together to improve strength. and bindingA finishing process to join pages together to form a book.. The post-press process gives the product its final look.

Image caption, Foil stamping

Image caption, Binding

1 of 2

As the paper-making process involves cutting down trees to create wood pulpWood fibres processed and reduced down with chemicals or mechanically broken down into smaller parts to make paper., as well as using harmful chemicals such as bleach, it is important that we can recycle paper and cardboard so that new wood pulp, needed to create paper, is kept to a minimum. Paper is made from celluloseA carbohydrate. It forms the cell wall in plant cells. fibres found in wood and grasses, which makes it renewableInexhaustible and replaceable..

Cost is also a consideration when designing, and designers should be able to calculate costs involved. It may be that different providers charge different amounts, and the designer will weigh up the comparison of cost and service before deciding who to use.

Example

A sheet of paper could be priced at 3p per A4 sheet. A manufacturer needing to purchase 1,000 sheets would use the following formula:

Total cost = 1,000 × 0.03 = £30.00

Note unit changed required: The price of each sheet of paper is given in pence, which needs to be converted to pounds.

Question

A designer requires 300 sheets of embossed A4 paper, costing 15p per sheet. What is the total cost?

Total cost = individual price × quantity needed

= 300 × 0.15 = £45.00