Digital design tools

As a result of advances in technology, it is common practice for digital technology to be used to aid the design, development and manufacturing of components and products. Digital design tools include:

- computer aided engineering (CAE)Used to test a computer aided design (CAD) through computer simulations, providing data to be analysed by designers.

- computer aided design (CAD)The process of creating a 2D or 3D design using computer software.

- computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer.

A design could start as a set of 2D sketches then evolve into a 3D CAD drawing of the part. rapid prototypingQuickly making models, usually by additive manufacturing (building up a 3D model in layers)., eg using 3D printing, can quickly allow it to be tested, evaluated and then finally machined using computer numerical controlled (CNC)The use of computers to control cutting and shaping machines and a key computer aided manufacture (CAM) technique. machinery, eg a CNC milling machine.

Image caption, Initial sketches

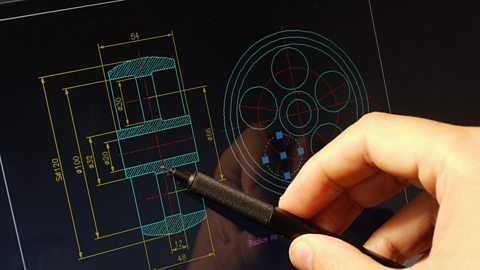

Image caption, An example of computer aided design (CAD)

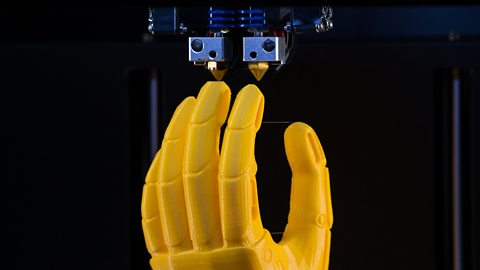

Image caption, 3D printing

Image caption, A computer numerical controlled (CNC) milling machine

1 of 4

Computer aided engineering (CAE)

Computer aided engineering (CAE) enables a designer to test and analyse the performance of a component or design through the use of computer simulation software. The use of CAE offers greater analytical capabilities in comparison to traditional testing, including:

- decreasing the lead timeThe time between the start of a project and the final product being manufactured. of a product

- enabling different materials to be tested for suitability

- reducing the cost of development

- decreasing development time as data can be analysed quickly

- allowing improvements to be made quickly as the files are digital

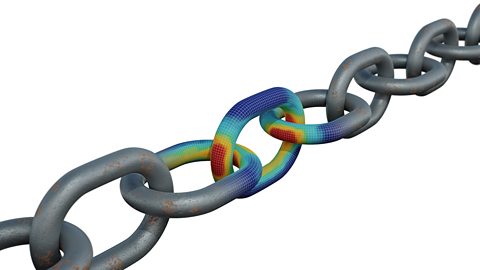

Finite element analysis (FEA)

finite element analysis (FEA)The use of computer simulation software to virtually test the engineering performance of designs. is the use of computer simulation software to virtually test the engineering performance of designs. This can include simulating how a structure performs under stress or strain or how heat and fluids are transferred in and around designs. An architect may use FEA simulations to test how a bridge would respond to loads being driven across it or the effect of winds blowing over it.

Computational fluid dynamics (CFD)

computational fluid dynamics (CFD)The use of software to simulate and analyse gas and liquid flow around a design. is the use of software to simulate and analyse gas and liquid flow around a design. For example, an aeronautical (airplane) engineer may use CFD testing to investigate the effects of different wing designs on the performance of an aircraft.

Shape optimisation

shape optimisationFinding an optimal shape for a part or a product. is a method of using computers to help in finding an optimal shape for a part or a product - maintaining its performance while reducing its weight. An example would be removing the excess material from a solid wheel to create spokes.

Computer aided design (CAD)

Computer aided design (CAD) software is a common feature of an iterative design A cyclic design process of modelling and testing to achieve gradual improvements to the design. process, allowing designers to create designs digitally in either 2D or 3D form. This can then be edited and manipulated quickly and can be exported to be used in computer aided manufacture (CAM).

Computer aided manufacture (CAM)

A product can be designed on a computer aided design (CAD) package and then sent to a computer aided manufacture (CAM) machine to be cut out, eg using a laser cutter. This can have a high initial cost so is often used in mass production or to create rapid prototypeThe first working model of a design used for testing, development and evaluation. at the start of a design process to save time and money.

Image caption, Computer aided design (CAD)

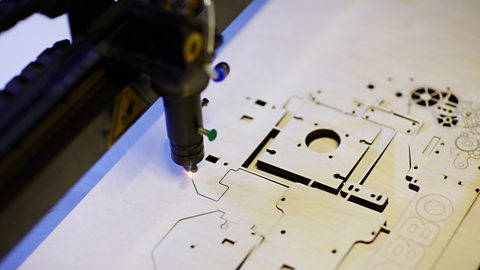

Image caption, Computer aided manufacture (CAM) - A laser cutter

1 of 2

Examples of CAM machinery include:

- computer numerical controlled (CNC)The use of computers to control cutting and shaping machines and a key computer aided manufacture (CAM) technique.milling machineA machine with a rotary cutter, used in cutting and shaping. - a cutter that will remove material in both X- and Y-axes whilst the bed of the machine moves up and down giving full three-dimensional cutting control from above, accurately removing around 0.5 mm at a time

- computer numerical controlled (CNC)latheA machine used to turn material so that it can be shaped to a cylindrical shape or bowl. - a cutter moves into the fixed material while spinning at high speed, accurately removing around 0.5 mm at a time to produce round shapes such as a plumb bobA weight with a pointed tip hung from string to create a perfect vertical line. or centre centre punchA sharp object used for making a dent, so a drill bit can find a centre point in preparation for drilling.

- laser cutterA machine that uses a laser beam to vaporise material and cut out shapes very accurately. - a laser passes through a small diamond, which focuses the laser beam and intensifies its power so that it can burn through material and cut out 2D shapes

- selective laser melting - a laser is used to melt a cross sectionAn end view or area of a 3D form. of the design in an incredibly thin layer of powdered metal, eg aluminum or steel, which hardens on top of previous layers and slowly builds up the shape

- 3D printing - layers of approximately 0.3 mm of extrudedShaped by being forced through an opening. material, commonly plastic but also metals such as aluminium, titanium and steel, are built up into a 3D solid

- stereolithographyA method of creating 3D models by building up layers. - a laser scans a bath of photosensitive Reacts to UV rays. resinRaw plastic, especially when in semi-liquid form., solidifying the cross section of the design before moving on to the next layer, it is beneficial in the production of metals as the parts produced through this process can be used to make master patterns for metal casting

Rapid prototyping

Rapid prototyping is the name given to a family of techniques that allow designers to produce scaled models or full size parts. It is an additive manufacturingA method of shaping a form by building on top of material. process, meaning material is added, and a common technique is 3D printing A method of adding material in layers to build a solid form.. Rapid prototyping is commonly used at the development stage as complex parts can be made quickly.