Wastage and addition

Most materials need specialist tools and equipment to shape and form them - polymers are no exception because of the unique propertiesThe mechanical, physical or optical properties of materials that define how they behave in use. they generally possess.

When marking out on the surface of a polymer, especially on a sheet of acrylic, a 'chinagraph' pencilA wax or grease-based pencil that can write on most non-porous surfaces. is used as this will mark on the glossyShiny. surface. If no such pencil is available, an alcohol-based permanent marker would also work to mark a line to cut to.

Polymers that are cut by hand are usually done by a coping saw, or sometimes a hacksawA common tool used for cutting metals and polymers. - if it is a smaller piece of polymer then a junior hacksaw can be used. Once the polymer is cut close to a marked line, a fileA common tool used for finishing and shaping. can be used to remove up to the desired line. Files can be bought in different shapes, sizes and cutting grades - a rough-cut file can remove polymers faster than a smooth file and should always be used first.

Plastics can be drilled by using a variety of different drill bits, which work by twisting into a piece of material:

- twist drills - used to simply drill a hole of a fixed diameter into a piece of timber

- countersink bits - used to profile a hole so that the top of a screw can sit flush with a surface

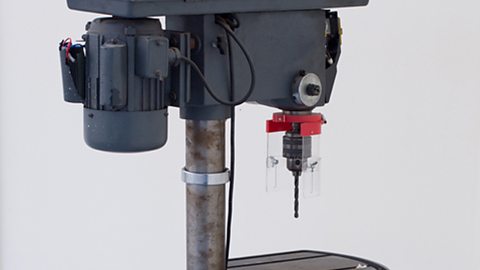

A pillar drillUsed to make round holes in timber and other materials. is used to improve production speed and to drill through various diameterA straight line which joins two points on the circle and passes through the centre is a diameter. of plastic.

Drill bits are inserted into the chuckUsed to hold a drill piece in place on a pillar drill and tightened by using a chuck key. of a pillar drill. Once the material is secured, the lever lowers the drill bits into the plastic, forming a hole. The clearance holeA hole through an object that is large enough to enable threads of a screw or bolt to pass through but not the shank of the screw or bolt. must be very slightly bigger than the shankThe head of a screw or bolt. of the screw. This is so that the shank can move freely in the clearance hole. The pilot holeA small hole drilled first as a guide to for a large hole or screw. must be smaller than the coreThe main thickness of a screw. of the screw so that the core fits tightly into it. If the screw head is to lie flush with the surface of the plastic, the hole must be enlarged or countersunk.

To ensure accuracy, jigA tool used to aid the repetition of a process and/or to hold a work in place. and formerA solid shape that is often used to make a mould. can be used during the process of drilling, bending and moulding plastic. Jigs and formers can also be reused to repeat the processes to produce identical products.