CAM and lasers

Specialist equipment is sometimes needed in production.

The importance of CAM in modern high-volume production

In modern production, designers and manufacturerA person or company that makes something from raw materials or from an assembly of component parts. use specialist equipment, known as computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer. machines. These machines are controlled through a computer, and are used in modern high-volume production.

Two examples of CAM machines used in the production of polymers are:

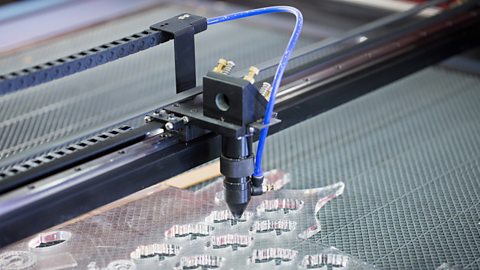

- laser cutterA machine that uses a laser beam to vaporise material and cut out shapes very accurately. - A laser is directed from a precise length on to a material to either cut or etch. The laser is controlled from a computer using a computer aided design (CAD)The process of creating a 2D or 3D design using computer software. drawing. Manufacturing can be restricted because of material choice and thickness.

- Computer numerical controlled (CNC) miller - Similar to a pillar drill, a milling machine uses a rotating cutting tool. This tool is able to move along multiple axes to create a range of shapes and designs. This movement is controlled through a computer using a CAD drawing.

Image caption, Laser cutter

Image caption, CNC milling machine

1 of 2

End of image gallery

| Advantages of CAM | Disadvantages of CAM |

| Creates products that are identical to each other | The software itself is expensive so initial costs are high |

| Drawings can easily be repeated for new batches | Machinery can be expensive and time consuming to repair |

| Enables very high accuracy levels in large-scale production | Users need to be trained how to use the software and machinery, which adds to costs |

| Usually speeds up production of low-volume products |

| Advantages of CAM | Creates products that are identical to each other |

|---|---|

| Disadvantages of CAM | The software itself is expensive so initial costs are high |

| Advantages of CAM | Drawings can easily be repeated for new batches |

|---|---|

| Disadvantages of CAM | Machinery can be expensive and time consuming to repair |

| Advantages of CAM | Enables very high accuracy levels in large-scale production |

|---|---|

| Disadvantages of CAM | Users need to be trained how to use the software and machinery, which adds to costs |

| Advantages of CAM | Usually speeds up production of low-volume products |

|---|---|

| Disadvantages of CAM |