Steph McGovern:Hello, I'm Steph McGovern, and I report for the BBC on all sorts of issues and news, to do with business, jobs and money.

Steph McGovern:Now because of my job I get to spend a lot of time visiting places like this, this incredible car factory, to look at how businesses work and how things are going for them.

Steph McGovern:We're deep inside the Toyota car factory here in Derby, where around 2,500 people make nearly 3,000 cars every single week. It's a 24 hour operation, where the production lines run along the most precise lines of efficiency. Now Toyota has led the way when it came to this kind of operation, and now car manufacturers everywhere work in a similar way.

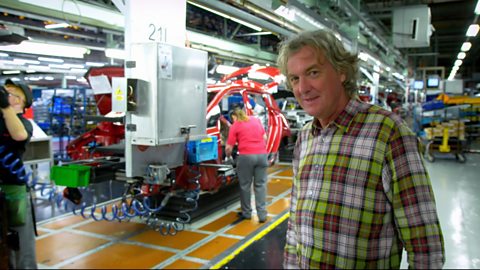

Steph McGovern:Everything on this production line is timed to the nearest second. And you pay for any delay. But even though there are lots of machines and robots, there's still a lot of people-power needed, as James May demonstrates in this clip from the Mini factory in Oxford.

James May:It's 6am.

Staff Manager:Morning, ladies and gents.

James May:The start of the day shift in logistics. These are the people whose job it is to make sure that the 6,000 parts for each car will arrive at the line exactly when they're needed. A system called just-in-time.

James May:Logistics manager, Hannah Crowder knows what it's like to work under pressure.

Hannah Crowder:It gets stressful with the amount of different processes and activities that are going on in the warehouse.

James May:Over half a million parts move through this vast warehouse every day.

Hannah Crowder:You definitely have to be calm and collected and structured to work in logistics.

James May:The just-in-time method works throughout the operation. Especially here in the warehouse. And it's all thanks to Bob.

James May:But Bob isn't a person, it's a computer system. When Bob demands parts, they're picked and taken to the dispatch area.

Hannah Crowder:So you've come at a really good time because it's really busy right now. All the tow trains are lined up ready to go. It's very important that they leave at the time that the monitor says. If they leave too early, we end up with too much stock at the line. And if they leave too late, then we have the potential risk of stopping the tracks.

James May:To keep the line moving, it's crucial that this relay race of parts works day after day after day. It's a race that can start thousands of miles away. The factory relies on a global network of suppliers, delivering parts both just-in-time and just-in-sequence.

James May:For some of these parts there's often just an hours' worth of stock on-site.

James May:Complex components like the engine, seats, and the car's iconic front-end are built off-site and have to reach the line on time and in exactly the right order.

James May:This is high stakes. Delays cost serious money and every second counts.

James May:It's the job of logistics general manager, Steve Prosser, and the team to keep things on track, no matter what.

Logistics Monitor:They've now closed the M40.

Steve Prosser:Yeah we've got a bit of an incident at the moment. M40 is our main corridor of parts, and we've just been notified that we've got issues southbound, between Banbury and Oxford. My experience of the M40 is once we have an issue there it backs up very quickly.

Steve Prosser:It's in real time that picture there is it?

Logistics Monitor:Yes, this is live.

James May:It's now 4pm.

Steve Prosser:The problem around Oxford is around 5 o'clock you start getting the rush hour, so even the A roads start to clog up.

Logistics Monitor:Southbound is now completely closed, northbound still flowing.

James May:The pre-assembled bumpers are coming from Banbury, and there's not enough on-site to keep the line running for much longer.

Steve Prosser:90 here already, so an hour and a half stock. Maybe 2 hours stock here, and their supply to us is normally every 45 minutes.

James May:Steve and his team liaise with the suppliers in real time, to divert the deliveries off the M40.

Steve Prosser:They've put a different route in for their next delivery to us.

James May:They keep a close eye on the roads and monitor deliveries with their track and trace system.

James May:It's good news.

Steve Prosser:This is their lorries coming through to us. Nothing on the M40 at the moment, so I'm quite happy about that. The assembly line is on plan as well, so all-in-all it's a pretty good day.

James May:It's one thing to reroute the lorries on the M40, but when parts can't get into the country in the first place, for example when there are problems with the Channel Tunnel, it can spell disaster.

Reporter:This traffic jam has been caused by strike action today, near the tunnel entrance.

Steve Prosser:We monitor the news, all the websites of the ferry, and also the Channel Tunnel, to see if there's any impact coming towards us.

James May:Extreme problems require extreme solutions.

James May:We use planes, trains and automobiles really to get parts here, to the site. And we have had helicopters into the site, and that's the kind of things that we do to get parts here.

James May:For the logistics team, getting parts to the line is a non-stop, round the clock operation. Whatever it takes, it is their job to deliver.

James May visits the BMW Mini factory in Cowley, Oxford to investigate how the 'just-in-time' method of stock control is used in car production.

Over 6,000 components go into making each Mini. Logistics manager Hannah Crowder explains that over 500,000 parts move through the Cowley warehouse every day.

A computer named Bob is used to pick parts, with tow trains then hauling boxes of components to the production line. A wall map shows the global supply chain, with parts sourced from across the globe.

Some parts have just one hour’s worth of stock on the Cowley site. For instance, the iconic front end of the car is made in Banbury and must arrive on time and in exactly the right order.

Any delays halt production in Oxford incurring significant costs. James talks with Logistics General Manager Steve Prosser about how the business manages unexpected events such as road closures on the local M40, preventing the delivery of bumpers from Banbury.

IT systems monitor traffic speeds on delivery routes, with real-time transport data then used to calculate stock levels, stock depletion rates and the predicted time of stock out. Channel tunnel closures set real challenges for logistics and helicopters may fly in parts if necessary.

Teacher Notes

Key Stage 4

This short film could be used to introduce the idea of stock control methods, just in case buffer stocks and just-in-time. Students might investigate the source of parts used in the production of goods made by factories in their local area, or nearby. Potential topics of discussion include the extent to which warehouses are needed to avoid the risk of stock out.

Curriculum Notes

This short film is suitable for teaching GCSE (KS4) / National 5 business.

Students and teachers over the age of 16 can create a free Financial Times account. For a Financial Times article about the UK car industry from 2024, click here.

More Business with Steph McGovern:

Lean car production. video

James May visits Nissan to investigate modern methods of production.

Market research and new car design. video

Exploring how Nissan uses market research to make design decisions.

The challenge of launching a new café video

Theo Paphitis advises a struggling café on how to adapt and survive.

The challenge of running a theme park. video

Declan Curry investigates business strategies used by Pleasure Island, a family owned theme park in Cleethorpes.

Kaizen - new ideas to improve productivity. video

How workers at Toyota come up with new ‘kaizen’ ideas every month.

Robots and automation in car manufacture. video

James May finds out how dancing robots are used to make Minis.

The rise and fall of Sunny Delight. video

Evan Davies explores why Sunny Delight took the market by storm but soon faded away.

How to market a new cereal. video

How Kellogg’s use marketing to launch a new product.