Steph McGovern:Hello, I'm Steph McGovern, and I report for the BBC on all sorts of issues and news to do with business, jobs and money.

Steph McGovern:Now because of my job, I get to spend a lot of time visiting places like this, this incredible car factory, to look at how businesses work and how things are going for them.

Steph McGovern:This is one of the UK homes of the Japanese car company Toyota, and even though we're in Derby, the influence of Japan is strong here because this place is a model of carefully planned efficiency, where everything is geared towards getting things done in the simplest, cleanest, quickest way possible.

Steph McGovern:It's something I know quite a bit about as well because I used to work in manufacturing, and was trained up in all of this, what we call lean production.

Steph McGovern:Now the key word here is "kaizen". That's "kaizen", Japanese for continuous improvement. So listen out for it in this next clip. I'm going to let James May explain it to you.

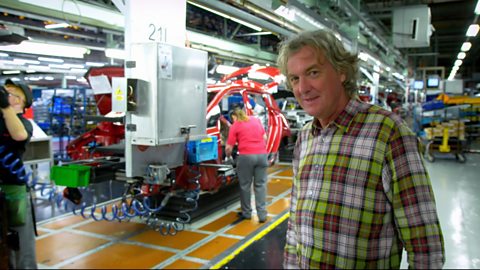

James May:At the Toyota factory in Derby every day begins with a strange ritual.

Staff Leader:One, two, three, four, five, six, seven, eight, nine, ten.

James May:Apparently these early morning exercises are a way of stimulating productivity.

Staff Leader:One, two, three, four, five, six, seven, eight, nine, ten.

ALL: Yosh!

James May:Yosh.

ALL: [LAUGHS]

James May:In fact, Toyota are obsessed with their quest for continuous improvement. It's a principal of the Japanese philosophy of lean production called "kaizen". Pioneered by Toyota, today it's used throughout the industry.

James May:Toyota have tried to kaizen every single part of their production system. Looking for ways to make it as efficient as possible.

James May:Take these ingenious machines. They deliver windscreens to the line, so Toyota's workers don't waste time fetching and carrying them. Each has its own song, so you hear them coming.

James May:This one's called Dougal. Dougal is Dave's brainchild.

James May:This all looks quite homemade, have you made these here?

Dave:All made in-house. That's steered by a wiper motor of an Avensis.

James May:Oh is it?

Dave:Yes.

James May:So is there an Avensis driving around somewhere with one stuck–

Dave:No. We had plenty of spare parts.

James May:You're not supposed to have spare parts, that's not just-in-time. How long before they get together and take over the world?

Dave:Hopefully not in my working life. [LAUGHS]

James May:I'm getting quite fond of these singing kaizen creations.

James May:Rather melancholy.

James May:Sets off on his lonely journey back to the windscreen fill-up point. Playing its mournful, baleful tune as it goes. Nobody cares.

James May:It's not the robots like Dougal that are clever here, it's the people who invented them.

James May:Kaizen is a team effort. Toyota encourage all their employees to come up with two kaizens every month. And today that includes me.

James May:But before I can come up with a kaizen, I need to learn how to do a job in the first place. So I'm getting a crash-course in steering wheel building, under the watchful eye of Toyota's kaizen guru, Gary Newington.

Gary:So this is a real-life situation.

James May:We're actually part of the production line?

Gary:Part of the production here.

James May:Gotta do it, gotta do it, gotta do it.

James May:After a quick demo, it's my time to shine.

James May:Two screws, dropped one.

James May:Getting these screws on is tricky.

James May:So that one goes there?

Gary:So have you come up with any kaizens? How you can think will make it easier to build?

James May:The screw thing is a bit… It's a bit fiddly.

Gary:Is it because you have to pick two?

James May:Picking up two is quite difficult, you know, I shake slightly because I'm so old and I then I got two on the floor.

James May:I don't think Gary trusts me, so I leave him and his team to knock up a kaizen. Suggestions for kaizens come from workers throughout the factory and it seems everyone I meet has one of their own. They're practical, like making these parts move with the worker.

Windshield Fitter:Over the space of 400 cars, it's a mile walk and a few seconds a car. And just saving that, or a movement like that. If you can get rid of that, that makes a difference.

James May:They're ambitious. This device moves windscreens right next to the car.

Windscreen Overseer:Previously, it was a manual operation. Now it's completely automated.

James May:It saved 6.3 seconds per car. But what amazes me is how miniscule time savings can have a massive impact.

Sticker Allocator:So what our kaizen department came up with for us, is a sticker picker.

James May:Turn it. There.

Sticker Allocator:Now you can just pick a sticker up very quickly.

James May:Do you want one on your watch?

Sticker Allocator:No, not the watch. Not the watch. [LAUGHS] So what this saves, it saves 0.3 of a second in picking the part, however we fit 96 to the vehicle. So across the shop, that’s 28.8 seconds per vehicle.

James May:Did you just work that out?

Sticker Allocator:It's right, trust me.

James May:With all this kaizen-inspired innovation, I'm intrigued to see how Gary and his team have solved the trouble I was having with the steering wheel screws.

James May:I like that already!

James May:They've built me a screw dispenser.

Gary:Give it a little push.

James May:Oh, look at that! Two! No more than two, no fewer than two.

James May:And attaching the screwdriver to this cord means it's exactly where I need it.

James May:Okay here we go with the new kaizen, new improved steering wheel thing. Right, this is where it gets interesting. Got my screw. Straight on there. Straight down. Much better!

James May:Kaizen!

James May visits a car factory in Derby to find out how Toyota use a technique called kaizen to improve efficiency and so stimulate productivity.

James explains that kaizen is the key element of the lean production approach to manufacturing. He interviews an employee who has designed and built a machine called Dougal that delivers windscreens straight to the production line.

Dougal saves time that workers once spent walking backwards and forwards from the store. Toyota encourage every worker to come up with two kaizen improvements every month.

James accepts the challenge to suggest his own kaizen improvement for building steering wheels. He notes that inserting screws to fix the steering wheel together is “fiddly”.

Other workers explain their own kaizen suggestions by which a few seconds saved can add up to significant cost reductions. For instance, eliminating a few steps collecting components, or cutting 6.4 second on the time taken to deliver windscreens to the production line.

A new ‘sticker-picker’ cuts 0.3 of a second off the time taken to pick up a sticky label that identifies parts. Overall this adds up to an overall time saving of 28.8 seconds in making one car.

James returns to the shop floor to find Toyota have designed a new machine that makes it quicker to make a steering wheel by dispensing two screws into his hand.

Teacher Notes

Key Stage 4

A real world example of how encouraging workers to be innovative can lead to small and continuous gains in productivity. Topics for discussion include the distinction between production and productivity and the impact of encouraging worker innovation on motivation and labour retention. Students could discuss how to reduce the time taken to distribute classroom resources such as exercise books or whiteboards during lessons and calculate the overall time saved for learning.

Key Stage 5

This short film demonstrates practical examples of how continuous kaizen improvements leading to small-time savings can have significant impact on costs. Students could investigate the potential for kaizen improvements at their own place of part-time work or at local businesses such as a café. To what extent does kaizen reduce the need for investment in new machinery to improve productivity?

Curriculum Notes

This short film is suitable for teaching GCSE (KS4) / National 5 business.

More Business with Steph McGovern:

Logistics, stock control and car manufacturing. video

James May visits Mini in Oxford to investigate 'just-in-time' logistics.

Lean car production. video

James May visits Nissan to investigate modern methods of production.

Market research and new car design. video

Exploring how Nissan uses market research to make design decisions.

The challenge of running a theme park. video

Declan Curry investigates business strategies used by Pleasure Island, a family owned theme park in Cleethorpes.

Robots and automation in car manufacture. video

James May finds out how dancing robots are used to make Minis.

The rise and fall of Sunny Delight. video

Evan Davies explores why Sunny Delight took the market by storm but soon faded away.

How to market a new cereal. video

How Kellogg’s use marketing to launch a new product.

The challenge of launching a new café video

Theo Paphitis advises a struggling café on how to adapt and survive.