Smart, modern and composite materials

The differences between smart, modern and composite materials

Traditional materials are those that have been in use for centuries, such as paper, wood, stone and metals. Further materials have been developed, such as modern materials and smart materials, which can be used alongside the traditional materials. Modern and smart materials are constantly being engineered, so it’s good to try to keep up to date with the latest developments. They can often be incorporated into new consumer products without people noticing.

Modern materials

concreteA particle-based composite made from cement and sand. Often combined with an aggregate such as stones or pebbles or reinforced with steel rods., aluminiumA chemical element often used for making drinks cans. and steelA ferrous metal composed of iron with small amounts of carbon to increase the strength. are all commonly used modern materials, but more-recent additions include materials that have changed the way we manufacture and use products.

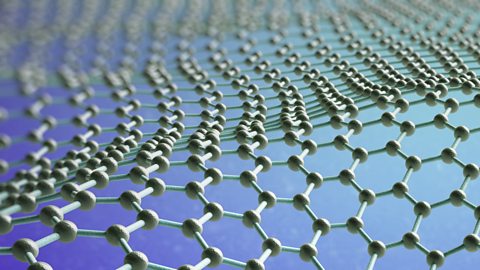

Graphene is a single carbon layer material which is hypothetically 100 times stronger than steel. It is hypothetical because we are yet to manufacture it in large enough quantities to prove this. In theory, it could provide body armour that is bulletproof, invisible and almost weightless.

If you covered the whole of Wembley Stadium in a layer of graphene, it would be almost invisible and be unbreakable, yet you would be able to lift it all with one finger.

Titanium is a modern metal and is used in sporting and medical applications, such as replacement hip joints and high-performance bicycles. It is an excellent material for these purposes as it has a high strength-to-weight ratio and is resistant to corrosion.

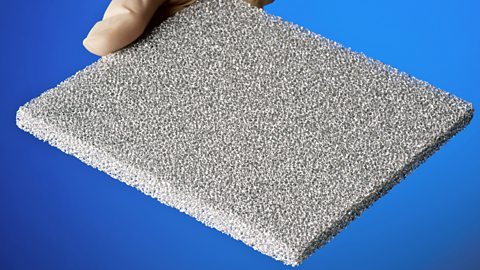

Metal foams are a strong but lightweight modern material produced by injecting a gas or foaming agentA material that facilitates the formation of foam. into moltenA term used to describe a liquid substance (eg rock, glass or metal) formed by heating a solid. metal. Typically, only 5-25 per cent of the foam is the metal, and this allows the material to retain much of its strength but without the densityCompactness of a material. or weight of a solid metal. Metal foams are often used in vehicles such as planes and cars as they absorb shock effectively if the vehicle crashes.

liquid crystal display (LCD)A visual display that uses liquid crystals. use the light-modulatingA beam of light is controlled using an optical modulator, which can control the current that powers the light source. properties of liquid crystals to display an image. The liquid crystals are between a liquid and solid state. When charge is applied to each liquid crystal, the shape changes to either block light or let light through. This ensures text or images display on the LCD.

LCDs require a backlight to work and many modern devices now use Organic Light Emitting Diodes (OLEDs) instead, which allows devices to be thinner and lighter. OLEDs are more expensive as each pixel is its own light, but they allow for thinner panels and better colour and contrastThe difference between lightness and darkness. An image with high contrast has very light (white) areas and very dark (black) areas. An image with low contrast is more grey..

Superalloys are a modern material and are typically used in modern aircraft where specific extreme properties are needed. As planes are put under extreme pressure forces and exposed to high levels of heat in the engines, they need to use materials that have excellent strength and heat resistance. The superalloys used are typically nickel, iron-nickel or cobaltA hard, magnetic material with a high melting point naturally found in the Earth's crust. alloys.

Nanomaterials are tiny particles of 1 to 100 nanometres (nm) that can be used in thin films or coatings such as the oleophobicA nanomaterial applied to a surface to repel oil and fingerprints. coatings on smartphoneA mobile phone with a powerful processor that is capable of running applications and accessing the internet. screens that repel greasy fingerprints, or hydrophobicA nanomaterial applied to a surface to repel water. materials that repel water.

Smart materials

While smart materials are modern materials, modern materials are not necessarily smart.

In other words, they change when you do something to them, and when you remove what is causing that change, they return to their original form.

Shape-memory alloys (SMA) are metal alloyAn alloy is a mixture of two or more elements, at least one of which is a metal. that can remember their shape when heated. These alloys have been utilised on spectacle frames that spring back to shape if they are squashed.

Nickel titanium (nitinolA smart metal composed of nickel and titanium that contracts when heated or exposed to an electrical current.) is a type of SMA, and it contracts when heated, whereas most metals expand. When braces are made from nitinol, they heat up in the mouth and ‘pull’ on the teeth, so they move with the nitinol.

thermochromicA temperature-sensitive pigment that changes colour when heated. change colour when their temperature changes. The term ‘thermo’ relates to heat, and chroma means colour - so thermochromic pigments change colour when they are heated up. These pigments can be mixed with paint or polymerA large molecule formed from many identical smaller molecules known as monomers. to give the materials the same colour-changing propertiesThe mechanical, physical or optical properties of materials that define how they behave in use. as the pigment. You may have seen this technology on colour-changing mugs or bath items for children.

Image caption, Body temperature can cause a reaction in thermochromic pigments

Image caption, Thermochromic pigments shown in use in a mug that reveals an image when heat is applied

1 of 2

Photochromic pigments work in a similar way but 'photo' refers to light - so these pigments change their properties when exposed to ultraviolet lightElectromagnetic radiation with a greater frequency than visible light but less than X-rays. Humans cannot see it but it can damage eyes and skin in high doses.. A well-known example would be glasses where the lenses are clear when worn inside a building, but become more like sunglasses when exposed to bright sunlight outside. The same technology has been used in windows to prevent rooms from getting too hot in warm weather.

Quantum-tunnelling composite (QTC) is an insulateTo help maintain the temperature. rubber containing tiny particles of metal. When squashed, the metal particles meet and allow the flow of electric currentThe movement of electrically charged particles, for example, electrons moving through a wire or ions moving through a solution.. As a result, QTC is an insulatorMaterial that is a poor conductor of electricity or heat. when resting and a conductorA material which allows charge to move easily through it. when pressure is applied. It is often used in outdoor applications where water might otherwise damage tiny microswitchesAn electric switch that is actuated by very little physical force through the use of a tipping-point mechanism, sometimes called an 'over-center' mechanism.. It has been used in clothing to control smartphones and portable music players, in power tools to give variable speed controls and in touch-sensitive pads.

Self-healing materials have the ability to repair themselves, which can extend the lifespan of the products that use them. These include polymerA large molecule formed from many identical smaller molecules known as monomers. that can heal knife cuts in themselves, metals that resist corrodeThe destruction of a metal by oxidation or chemical action, eg rusting. and concrete that can heal when cracked.

Ferrofluids can be formed by a magnetic fieldArea surrounding a magnet that can exert a force on magnetic materials. and are being used in hydraulic suspension pistons, with the strength of the magnetic field allowing the suspension to be hard or soft depending on what is necessary. They also have frictionA force that opposes or prevents movement and converts kinetic energy into heat. reducing properties allowing magnetic objects to glide across the surface.

Polymorph is a polymerA large molecule formed from many identical smaller molecules known as monomers. that becomes malleableCapable of being hammered or pressed into a new shape without being likely to break or return to the original shape. when heated to about 62°C. When it cools down it becomes hard enough to drill and cut. This makes it perfect for modelling as it can be reheated and formed again. It is also excellent for creating ergonomic handles and models.

Biopolymers

These are polymers that are produced by living organisms. As a natural resource, biopolymers are biodegradableMaterial that can be broken down in the environment by microorganisms. and will naturally compost. Biopolymers can come from starch, sugar, celluloseA carbohydrate. It forms the cell wall in plant cells. or synthetic materials.

Biopolymers are seen as beneficial to the environment as they are a sustainableMeeting the needs of today, while also ensuring future generations can be provided for. natural resource that naturally decompose and do not produce carbon emissionsThe release of carbon dioxide gas into the atmosphere..

| Biopolymer | Source | Uses |

| Starch-based biopolymers | Natural plant tissues on potatoes, maize and wheat - starch can be melted and then deformed | Ideal for extrusion and injection moulding due to their strong water resistance |

| Sugar-based biopolymers | Sucrose or starch through bacterial fermentation | In surgical implants such as heart valves and joint replacements and in medication as they produce no side effects when breaking down in the body |

| Cellulose-based biopolymers | Wood or cotton - the cellulose liquid is repeatedly treated with different chemicals until it appears as a thin soft transparent material | For thin food wrappings, such as cellophane packaging |

| Synthetic-based biopolymers | Derived from petroleum | On substrate mats in terrariums - will naturally decompose and compost |

| Biopolymer | Starch-based biopolymers |

|---|---|

| Source | Natural plant tissues on potatoes, maize and wheat - starch can be melted and then deformed |

| Uses | Ideal for extrusion and injection moulding due to their strong water resistance |

| Biopolymer | Sugar-based biopolymers |

|---|---|

| Source | Sucrose or starch through bacterial fermentation |

| Uses | In surgical implants such as heart valves and joint replacements and in medication as they produce no side effects when breaking down in the body |

| Biopolymer | Cellulose-based biopolymers |

|---|---|

| Source | Wood or cotton - the cellulose liquid is repeatedly treated with different chemicals until it appears as a thin soft transparent material |

| Uses | For thin food wrappings, such as cellophane packaging |

| Biopolymer | Synthetic-based biopolymers |

|---|---|

| Source | Derived from petroleum |

| Uses | On substrate mats in terrariums - will naturally decompose and compost |