Plastics

Plastics are a relatively new syntheticA material made by a chemical process, not naturally occurring. material. They can be created from organic sources such as plants and also from substances such as crude oil and coal. Plastics are a very versatile material and they can be used to produce a wide range of goods.

Most of the plastics in common use today are a by-product of the oil industry. They have usually gone through a long period of development and processing to get them to the stage where they can be a material used in manufacture.

| Advantages | Disadvantages |

| Plastics come in many forms such as powder, liquid, granules, sheets and different shaped rods | The production of plastics can be very harmful to the environment |

| Plastics can have different properties - some are light and strong or resistant to electricity and corrosion | Non-recyclable plastics can be very hard to dispose of safely. They can take many years to decompose and break down |

| Plastics are easily shaped and come in variety of different colours and textures | |

| Many plastics can be recycled |

| Advantages | Plastics come in many forms such as powder, liquid, granules, sheets and different shaped rods |

|---|---|

| Disadvantages | The production of plastics can be very harmful to the environment |

| Advantages | Plastics can have different properties - some are light and strong or resistant to electricity and corrosion |

|---|---|

| Disadvantages | Non-recyclable plastics can be very hard to dispose of safely. They can take many years to decompose and break down |

| Advantages | Plastics are easily shaped and come in variety of different colours and textures |

|---|---|

| Disadvantages |

| Advantages | Many plastics can be recycled |

|---|---|

| Disadvantages |

Thermoplastics

Thermoplastics are the most commonly used plastic due to the properties they possess. These plastics can be heated, moulded into a shape, and then reheated back to their original shape because their molecules are able to restructure themselves with something called 'plastic memory'.

These materials have a low melting point which means it can be used in a variety of manufacture techniques.

Examples of thermoplastics include:-

- ABS (acrylonitrile butadiene styrene)

- acrylic

Thermosetting plastics

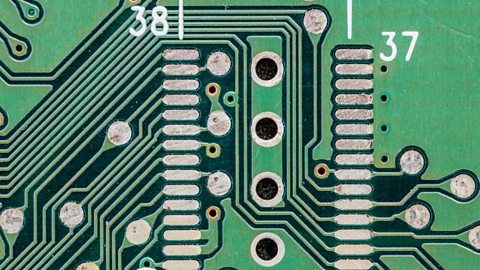

The molecular structure of thermosetting plastics doesn't allow the molecules to restructure themselves. This mean the materials can't be reshaped or recycled. Their structure does mean that they are very resistant to heat, electricity, chemicals and scratches.

Because of these properties, thermosetting plastics can be found in products such as electrical fittings and circuit boards.

Examples of thermosetting plastics include:-

- melamine

- urea formaldehyde