Commercial processes

A commercial process is a method of manufacturing that takes place in industry. For timber this includes:

- routingA process of using a rotary cutter to shape and cut material. - using a router

- turningA method of spinning a material so that a cylindrical shape or bowl can be produced. - using a lathe

Routing

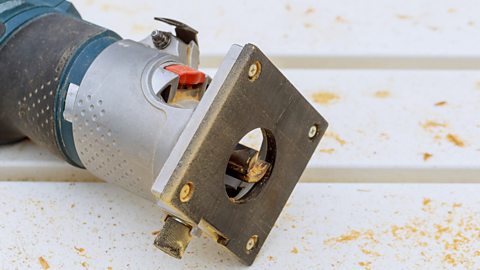

A router can either be hand-held, mounted to a table or even computer controlled. All routers work by rotating a cutting bit at high speed. As the cutting tool passes over or along the edge of the timber, a cut or profiled shape is made. Routers can plunge into a material to cut holes. They can follow jigA tool used to aid the repetition of a process and/or to hold a work in place. or patternRepeated design or recurring sequence., for example kitchen fitters might follow a pattern to join worktops together.

A hand-held routerA rotary cutter that is not fixed to a machine bed. A hand-held router can be used to cut and shape material. is either plunged down onto the timber or moved along an edge. A table routerAn inverted router that is fixed to a table. is fixed upside down so that the cutter protrudes from the table top. Both types of router produce the same effect. A computer controlled router, or computer numerical controlled (CNC) routerA method by a computer to execute a pre-programmed sequence. Machines move via numerical values along X, Y and Z axes., works by following a cutting path that has been designed on a computer. The material to be cut is fixed to a cutting bed so that the router is the only part that moves.

Image caption, Hand-held router

Image caption, Table router

1 of 2

Turning

A lathe works by spinning a piece of timber at speed. While the timber is turning, a wood-turning tool is pushed into the timber to change its shape. Some timber can be held in place by compressing it from end to end. This would allow a spindleA cylindrical-shaped piece of material. or cylinder to be shaped. Another way to hold the timber in place is to screw it to a faceplate - the timber then spins on the lathe, and this would allow a bowl to be turned.

Image caption, Turning a spindle on a lathe

Image caption, Timber screwed to a faceplate to turn a bowl

1 of 2