Refining ideas

Developmental research

The iterative design A cyclic design process of modelling and testing to achieve gradual improvements to the design. process continues with the development of designs, focusing on improving them and making them more successful. It is important at this stage for designers to consider the design as a whole, rather than the separate componentA part that when put together makes a product. in isolation.

It is crucial for designers to incorporate user feedback into their design decisions as it will help in generating and evaluating new developmental ideas and produce a successful chosen design. Developing ideas will highlight areas of uncertainty that may require further research to strengthen the success of the idea:

- Which areas of the design specification does the design not meet? What could the designer find out to help meet these criteria?

- Could successful features from other ideas or existing products be merged to make the design more successful?

- How will the product actually work?

- mechanismParts that work together in a machine., eg ways of opening or moving

- componentA part that when put together makes a product., eg timers, bulbs, hook and loop fasteners etc.

- How could it be manufactured?

- Are there any potential sustainability issues?

- Are there any potential safety implications, or does it comply with standards, eg British Standards Institution (BSI)?

- How could it appeal to the user more?

- more in-depth research about users, user conditions and values

- ergonomicsThe science of designing the product to fit the user, or the job to fit the worker. and anthropometricsThe study of body measurements. research

Modelling and simulation

Modelling can be time consuming and expensive, but a physical model allows a person to see and handle a product unlike viewing it on a screen through computer aided design (CAD)The process of creating a 2D or 3D design using computer software..

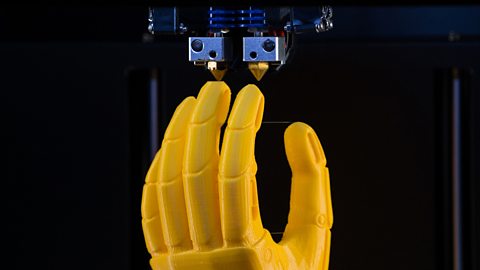

computer aided manufacture (CAM)The manufacture of a part or product from a computer aided design (CAD) using computer-controlled machinery, such as a 3D printer. models made on a 3D printer using a CAD drawing are very accurate but also expensive, time consuming and limited to 3D-printable materials.

Designers can use easy-to-form and easily accessible materials, eg balsaA lightweight hardwood used for modelling., jelutongA low-density wood used for modelling. and cardboard, to create cheap models quickly and cheaply. Creating a scale model helps to test and evaluate the design before final production. The model helps to visual the finished product and can be reviewed against the design brief and specification.

prototypeThe first working model of a design used for testing, development and evaluation. can be full-size, working models of a product, and are the next stage of development after modelling. They are often made from the same material as the product and often have fully functioningWorking. parts. Prototyping is expensive, so a product needs to have already been modelled and tested.

Reasons for prototyping

- manufacturing plans can be made, allowing for the planning of cost, materials and quantityAmount of a product or material.

- following clientIn business, a client is a person or organisation that wants a product manufactured, eg a retailer. and user feedback, small changes and improvements in aestheticHow something looks. and functionThe purpose or reason. can be made before production starts

- user trialTesting a product with a group of customers before taking it to the market. with a prototype can check functionality, marketability and whether a product is fit for purpose before spending money on production

- specialist tools and equipment can be planned for and costed for when the product is later produced for the mass marketThe market for goods that are produced in large numbers.

Prototyping can help work out the cost of manufacturing a product, including how much material is needed and what machinery is required. The percentage profit can be worked out from this and can be improved by lowering production costs, for example by using cheaper materials or fewer workers.

Once a prototype has been made it can be tested in a variety of ways:

- destructive testing - tests the product to its extreme to see what conditions it can tolerate before being destroyed to help decide on the best materials and construction methods to use

- non-destructive testing - tests the model to identify areas of weakness without destroying it to test the function of the product and highlight any unexpected design flaws

- market testing - tests the product with its target marketThe group of people a product is made for. to gain feedback on performance and design

Analysis, evaluation and modifications of design ideas

Throughout the iterative design A cyclic design process of modelling and testing to achieve gradual improvements to the design. process, the design ideas and models or prototypeThe first working model of a design used for testing, development and evaluation. will need to be analyseTo examine in detail. and evaluateTo judge the quality and performance of a product. to inform the choice of design to take forward, to make modifications and to allow the final chosen design solution to be developed.

The designer will also need to consider:

- suitable materials - materials have different propertiesThe mechanical, physical or optical properties of materials that define how they behave in use. and should be selected appropriately

- suitable techniques and processes - these will be partly defined by the selection of suitable materials

- feedback from users

- developmental research

These considerations, as well as the design briefA set of instructions given to a designer by a client., design specificationDocument containing details of a product's required characteristics, and all the processes, materials and other information needed to design the product. and feedback from the user, must be constantly utilised to ensure that the designer stays on the right track and produces a successful chosen design.