UNKNOWN FEMALE:'This isn't just a beautiful wing, inside this wing are the fuel tanks and a very complex fuel system.

UNKNOWN MALE:It's an old saying, there's no hard shoulder at 35,000ft.

NARRATOR:'The Airbus A380 is the world's largest airliner.

NARRATOR:'The wings that carry this superjumbo need to be able to take enormous loads and stress flight after flight, and still be safe and reliable. That's why constant testing for fitness for purpose is crucial.

NARRATOR:'As chief engineer responsible for the ongoing development of the wing, John Roberts is on his way to the Garman city of Dresden, to visit one of his most important test sites.'

JOHN ROBERTS:I mean, I've got probably the best job in the factory. It's a great job, looking after this aeroplane. And they pay me for it as well, which is good.

NARRATOR:'The Dresden rig is a test structure so large it took two years to build.'

JOHN ROBERTS:'You always get a buzz of excitement seeing the sheer scale of this test facility that we do here. If you don't get any excitement out of things like this, you're in the wrong business.'

JOHN ROBERTS:And here we are. Welcome to IABG in Dresden.

NARRATOR:'What John's engineers are after is proof that the superjumbo and its wings are strong enough to last a lifetime of flight.

NARRATOR:'To find out, they've spent well over £100 million on the largest test rig of its kind ever built.'

SPEAKS GERMAN

NARRATOR:'The rig is essentially a giant torture machine, to expose any weaknesses in the design of the plane's structure that might develop, by simulating the kind of stresses a real plane would experience in flight, over and over again.'

JOHN ROBERTS:The most interesting part of this test is the bit which takes all the punishment. The aircraft when it's flying, all its loading is being taken up on the wing, which you can see up there.

JOHN ROBERTS:'So all the punishment is being driven into the wing structure. And this is a demonstration of what it looks like while it's actually in flight.'

NARRATOR:A computer system drives a network of 180 hydraulic rams that bend and distort the wings.'

JOHN ROBERTS:It bends, doesn't it?

JOHN ROBERTS:You can never fail to be impressed on seeing something like that.

NARRATOR:'Computer modelling of real journeys means that, in this simulation, flight times can be reduced to only the bits of the journey where the plane is particularly stressed, like turbulence and landing.'

JOHN ROBERTS:This would be a window an ordinary passenger might be looking out along the wing, in the test here, the end of the wing is moving up by over four metres during normal flight cycles, and down when it's on the ground, by nearly two metres.

JOHN ROBERTS:People always look out along the wing and see it bouncing up and down in turbulence and thinking, "Is this something that I should worry about?" Well, we test it with the assumption that it happens all the time. No, you don't need to worry about it.

NARRATOR:'And precise engineering ensures the wings bend in exactly the right way.

NARRATOR:'The ability of the wing to take huge punishment is down to the design of its structure. It needs to be light, but also very strong.

NARRATOR:'Inside, this structure is like a skeleton, with ribs and spars which provide stability and support and also withstand external forces.

NARRATOR:'The ribs and spars are made from aluminium and carbon fibre composites. Materials known for their flexibility, lightness and strength.

NARRATOR:'And this test is the pinnacle of the whole testing program to prove the plane is safe to fly.'

JOHN ROBERTS:In terms of proving the aircraft is safe, you have to put together a portfolio which shows everything from the individual little valve that sits within the wings through to the complete structure test.

JOHN ROBERTS:We always joke that when the paperwork is heavier than the aeroplane, you're about close to getting it right.

NARRATOR:'Tests like this are being carried out all the time, to help engineers make great designs come to life.

Video summary

This short film, first published in 2011, is for teachers and review is recommended before use in class.

The Superjumbo wing must flex and twist and undergo stresses and movement in flight.

We find out how the industry makes sure that it is safe for use and gain an insight into the importance of test rigs in the testing of a product for safety and fit for purpose.

A £100 million test rig is seen in action, that simulates the stresses a real plane experiences in flight repetitively.

The importance of precise engineering is emphasised.

A description of the Superjumbo wing structure, with its ribs and spars, to allow the wing to bend in exactly the right way is also revealed.

Teacher Notes

Could be used to introduce students to physical testing procedures.

They might be asked to reflect on the advantages and disadvantages of using virtual simulations on computers compared to physical testing.

As a starter activity, they might be asked to match a range of linear (such as beams, struts, ties and columns) and surface (such as shells, panels, membranes and ribs) elements to images of frame, shell and composite structures.

Following this, students might design reinforcements to frame and shell structures, using appropriate technical terms and structural elements.

This clip will be relevant for teaching KS3 and KS4/GCSE Design and Technology, materials.

This topic appears in OCR, Edexcel, AQA, WJEC in England and Wales, CCEA in Northern Ireland and SQA National 4/5 and Higher in Scotland.

How satellites are tested. video

Find out how a satellite is tested in order to survive in space for 15 years.

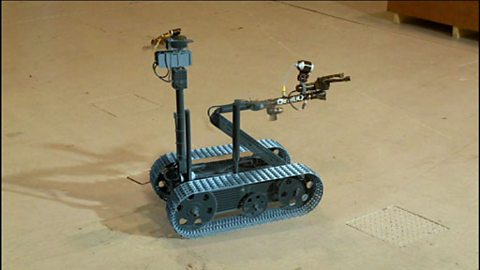

How robots are used in risky situations

How robots can be used in work

Building a supercar. video

Formula One team McLaren show us the production floor of their supercar, the MP4-12C.