The forge in Woodbastwick has been in disrepair for years and it wasn't until recently that engineer Michael Harvey decided to renovate it. When Michael was made redundant from his job several years ago, he decided to have a change in life direction. His son Greig had just started an apprenticeship as a blacksmith and farrier and as Michael had always had an interest in blacksmithing, he decided to take up the challenge of restoring the old forge in Woodbastwick. The project has been a great labour of love for Michael and Greig. Although it has proved expensive, seeing the restored forge has more than made up for the cost. Michael said, "We've had to replace a great part of the roof, there was even ivy growing in the fireplace, but it's great to see it looking as good as it has in about a hundred years." Michael and his son spent months clearing the forge of ivy and blackberries before they were able to call in the builders for restoration work. The forge was finally opened in 1993 after nine months of building work and preparations. Michael's new role in life is based on a passion he developed as a hobby in his back garden. He said of his work: "It does take a long time and bit of concentration. Nothing's difficult if you do it enough, but they do take a little bit of getting used to and getting to grips. It took me a long time to get up to this standard, a lot patience and a bit of swearing on the quiet," he added.

Greig hard at work making a horse shoe |

Michael's makes includes fashioning weather veins, pokers, church clock faces, gates and even crooks for the Bishop of Norwich and the Arch Bishop of Canterbury. While he is working on garden furniture, his son Greig is out and about shoeing horses. Greig can be found in the forge every Monday making horse shoes for the week ahead using a technique that's changed little over the years. Greig said, "The basics of it remain the same, going back to the Romans who developed the idea of putting iron shoes on horses." "Certain modern techniques have come in including plastic shoes which are glued to the foot, but 95% are still shod in the conventional method of steel shoes nailed to the horses foot with slight variations of methods and techniques," he added. Many centuries ago, the blacksmith's forge was at the heart of village life, not only providing horse shoes but tools used by the carpenters, thatchers and housewives. In some cultures today the skill is still greatly revered.

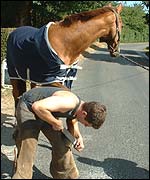

Greig puts a shoe on a horse |

Michael said "I think in some of the African countries they regard the blacksmith as something of a wizard, he can join two pieces of metal together just by putting them in the fire - that must be magic." Normally Greig goes out to the horses but local woman Julie Edmonds had to make an emergency visit to the forge when the horse she was looking after lost a shoe. Greig said of replacing the horse shoe, "Knocks and lumps are a daily occurrence. I had a nasty knock to the head which put me out of action for a day, and bites as well - it's a risky game!" "His mother reckoned the kick in the head did him good!" laughed Michael. See more Restoration stories » |